HANWHA HCR-12A

Robot o udźwigu 12 kg i zasięgu 1300 mm dedykowany do przenoszenia ciężkich elementów, załadunku i rozładunku. Szczególnie przydatny przy paletyzacji gdzie wymagany jest duży zasięg działania i duży udźwig. HCR-12A doskonale się sprawdza w ciężkich aplikacjach jak spawania, polerowanie i malowanie. Zasięg robota może zostać wydłużony o dodatkowe 300 mm przy zmniejszeniu udźwigu do 10 kg.

Liczba osi

6

Zasięg

1300 mm

Powtarzalność

0.05 mm

Ładowność

12 kg

Powierzchnia

220×227

mm

Warunki pracy

IP 54

Dane techniczne ramienia HCR-12A

Udźwig

12 kg

Zasięg ramienia

1300 mm

Ilość stopni swobody

6

Prędkość narzędzia

1 m/s [max.1.2 m/s]

Waga

51 kg

Powtarzalność

±0,05 mm

Stopień ochrony obudowy

IP 54

Temperatura pracy

0-50°C

Długość kabla kontrolera

6 m [10 m opcja]

Obudowa ramienia robota

aluminium – stal

Typ złącza narzędzia EOAT

3 x M8 | 8-pin + EtherCAT

Mocowanie narzędzia EOAT

ISO9409-1-50-4-M6

Wejścia cyfrowe

4

Wyjścia cyfrowe

4

Wejścia analogowe

2

Certyfikaty

EN ISO13849-1, Cat 3, PLd, EN ISO 10218-1, CE MD, KCs

Zasięgi przegubów

J1: ±180° J2: ±150°

J3: ±165° J4: ±190°

J5: ±170° J6: ±360°

Szacowany czas pracy

35 000 rbh

Dane techniczne - Pilot uczenia

Wymiary

340x268x81 mm

Waga

1.8 kg

Ekran

12″, 1024×768,

dotykowy rezystancyjny

Interfejs użytkownika

GUI, Przyciski: Power,

Emergency Switch

Długość kabla

5 m

Akcesoria

uchwyt do trzymania

Temperatura pracy

0-50°C

Obudowa pilota

tworzywo sztuczne

Dane techniczne - kontroler

Wymiary

450x470x223 mm

Waga

19.8 kg

Komunikacja

TCP/IP, EtherCAT,

Modbus TCP

opcja: EthernetIP, Profinet

Zakres detekcji siły

25-150 Nm

Porty we/wy

16 wejść cyfrowych [PNP]

16 wyjść cyfrowych [PNP,

max.200 mA]

Analogowe: 2 wejścia, 2 wyjścia

Zasilanie

100-240 VAC, 50-60 Hz

Temperatura pracy

0-50°C

Obudowa

stal ocynkowana,

malowana proszkowo

Poziom hałasu

≤ 70 dB

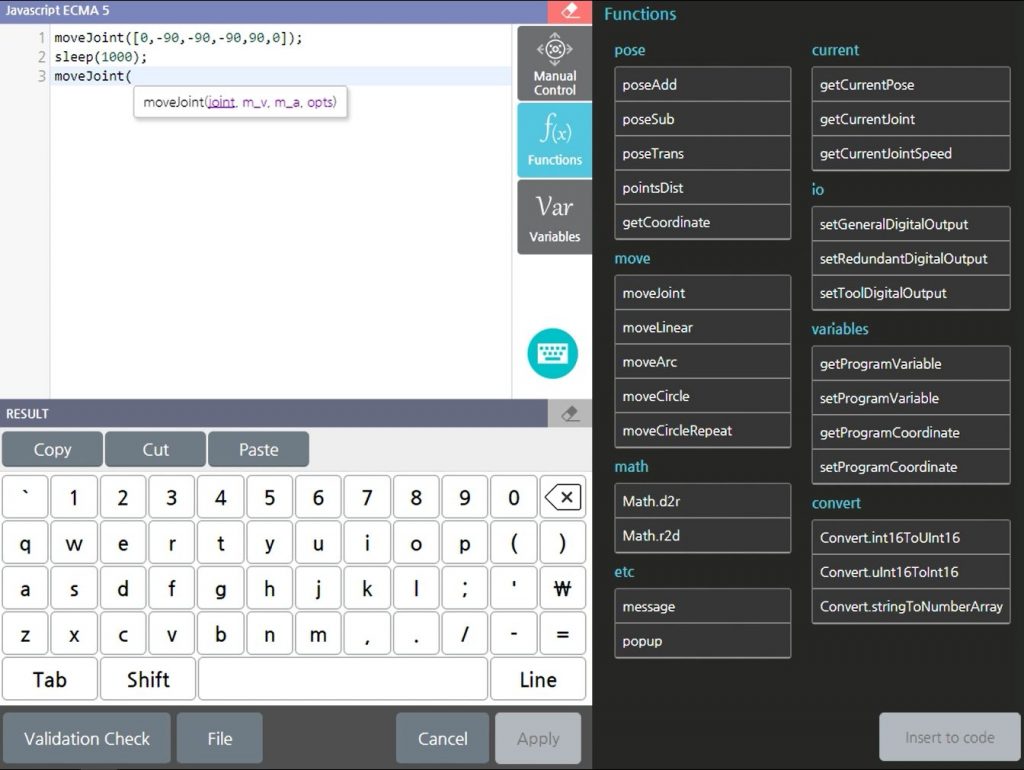

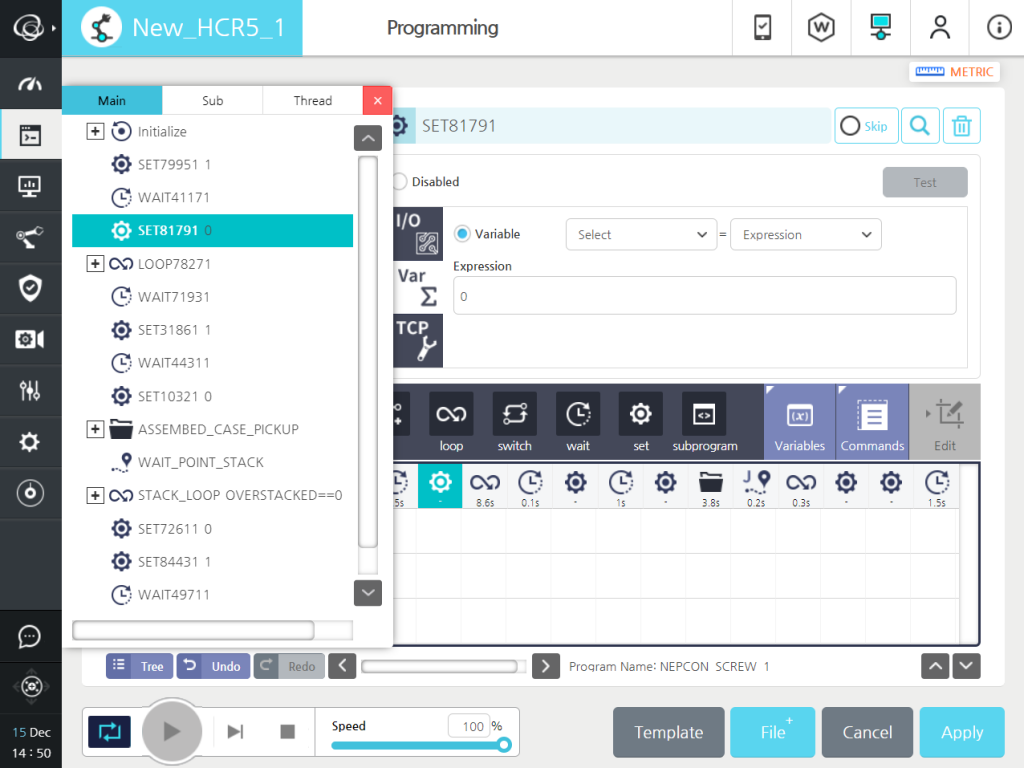

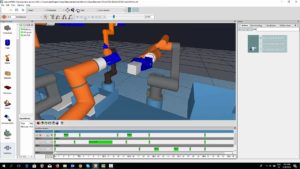

Oprogramowanie RODI

Intuicyjne oprogramowanie RODI z graficznym interfejsem użytkownika pozwala łatwo obsługiwać robota HCR-12. Używanie tradycyjnych robotów przemysłowych wymagało wiedzy programistycznej i wielotygodniowych szkoleń. Oprogramowanie RODI pozwala łatwo i intuicyjnie programować roboty osobom bez wiedzy eksperckiej. W celu zaprogramowania wystarczy umieścić na osi czasu odpowiednie ikony, skorzystać z gotowych szablonów lub programów.

Zalety RODI

- Intuicyjny graficzny interfejs użytkownika

- Przyjazne ikony umieszczane chronologicznie na osi

- Gotowe szablony najczęściej używanych funkcji

- Gotowe programy

- Łatwa integracja z zewnętrznymi urządzeniami

- Gotowa baza urządzeń Plug’n’Play

Krok po kroku z wizualizacją 3D

Opcjonalne możliwości własnych algorytmów

Intuicyjne programowanie na osi czasu

Aplikacje

Przeczytaj również na temat Cobotów

Nowy Cobot HCR-14 Rodzina robotów HCR z Hanwha Robotics rozszerza się o kolejny model HCR-14 o udźwigu 14 kg i zasięgu 1420 mm. Robot ten...

Automatyzacja i robotyzacja obsługi maszyn CNC Czy robotyzacja obsługi maszyn CNC wzmacnia konkurencyjność firmy? Zdania są podzielone. Z jednej strony obsługa maszyny CNC to nudna,...

Jeden chwytak – wiele możliwości Odkryj nowe możliwości automatyzacji produkcji żywności i napojów, kosmetyków i farmaceutyków dzięki certyfikowanemu miękkiemu chwytakowi SoftGripper Z łatwością manipuluj szeroką...

Roboty współpracujące Coboty czyli inaczej roboty współpracujące, stają się elementem większości fabryk na całym świecie. To one dzięki swojej łatwości programowania porównywalnej do obsługi smartfona...

Obsługa maszyn robotem współpracującym

Obsługa maszyn zawsze wiązała się z monotonną pracą tuż obok niebezpiecznych maszyn. Pojawienie się robotów współpracujących całkowicie zmieniło reguły gry w tym zakresie. Sam zobacz

Metody programowania robotów przemysłowych

Jakie są metody programowania robotów przemysłowych? Dynamiczny rozwój robotyki w ostatnich latach spowodował, że programowanie robotów przemysłowych stało się poszukiwaną specjalizacją. Samo programowanie robotów przemysłowych

AKADEMIA HCR ONLINE

Naucz się programowania cobota HCR OnLine Teraz wystarczy kilkadziesiąt minut by nauczyć się konfiguracji, programowania robota. Przygotowaliśmy materiał w postaci kilku filmów pokazujących krok po

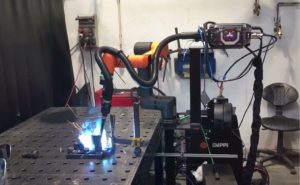

Cobot spawalniczy – czym jest?

Cobot spawalniczy – czym jest? Spawanie historycznie zawsze było procesem trudnym, który wymaga skupienia i precyzji. Z drugiej strony spawanie to ciężka praca w trudnych

AUTOMAPPPS – łatwo i szybko przygotuj każdą aplikację

Kolejne narzędzie dostępne dla robotów HCR. AUTOMAPPPS to oprogramowanie, które umożliwia pełną symulację stanowiska, aplikacji i pracy robota wraz z określeniem kluczowych parametrów. Oprogramowanie umożliwia

Kolejna aplikacja spawania z HCR

Przemysłowy Robot Współpracujący HCR w kolejnej aplikacji pokazuje, że można łatwo i szybko spawać używając go jako robota spawalniczego HCR-5A7 lub HCR-12A7. To w pełni

Automat spawalniczy

Automat spawalniczy Automat spawalniczy to rozwiązanie do efektywnego automatyzacji spawania. Dodatkowo dzięki ramieniu robota, które precyzyjnie pracuje z wysoką dokładnością i powtarzalnością unikamy słabych stron

Kolejna aplikacja HCR

Zobaczcie jak dwa roboty HCR-5 efektywnie wykonują operację montażu połączoną z obsługą maszyny i transporterów. To proste i efektywne narzędzie robotyzacji procesów produkcyjnych. Powiązane wpisy:

SmartPalletizer – łatwa i szybka paletyzacja

Paletyzacja to jedno z łatwiejszych zadań dla robotów. Sam zobacz!!! SmartPalletizer to gotowy zestaw, który ustawiasz na końcu linii produkcyjnej. Robot HCR przez 24 godziny

Spawanie cobotem dużych elementów

Ostatnio mieliśmy niezwykłą okazję wdrożyć innowacyjne rozwiązanie w fabryce naszego Klienta – spawanie za pomocą dwóch cobotów jednocześnie, zamocowanych do sufitu, które współpracują z dużym

Kartoniarka czy robot do rozkładania kartonów?

Robot do rozkładania kartonów to więcej niż kartoniarka Rozkładanie i klejenie kartonów to żmudna praca o małej wartości dodanej. Dlatego w przeszłości wymyślono kartoniarki. Jednak

HCR zdobywa złoty Medal Automaticon 2019

Przemysłowy Robot Współpracujący HCR produkowany przez firmę HANWHA i dystrybuowany przez CoRobotics znalazł się w gronie 5 finalistów i otrzymał prestiżową nagrodę na Targów Automaticon

Roboty współpracujące HCR, pracują nieprzerwanie przez 24/7/365 wykonując zadania w trudnych warunkach. Zapewniają 100% powtarzalność, dokładność wykonywanej pracy.

Liczne aplikacje w kraju i zagranicą, potwierdzają szybki zwrot z inwestycji w robota HCR. Robot, dzięki swojej elastyczności zastosowań i szybkości wdrożenia, zwraca się już w 6 miesięcy a spotykamy aplikację gdzie zwrot następuje już po 2 miesiącach. To przypadki gdzie precyzja robota pozwala zminimalizować straty materiałów i eliminację kosztownych błędów jakościowych.

Po wyjęciu robota HCR z pudełka wystarczy godzina na uruchomienie i zaprogramowanie pierwszego zadania. Roboty HCR wyposażone są w intuicyjny graficzny interfejs użytkownika w 3D, który pozwala na zaprogramowanie robota już po kilkudziesięciu minutach nauki. W prosty sposób możemy pokazywać, co robot ma zrobić – poruszając jego ramieniem z punktu do punktu, możemy zapisywać skomplikowane ścieżki ruchu przez pokazywanie, co jest szczególnie przydatne w aplikacjach wymagających złożonych ruchów. Wdrożenie robota nigdy nie było tak szybkie i łatwe.

Roboty HCR są zaprojektowane do ciężkiej pracy ciągłej w warunkach przemysłowych. Pracują wytrwale przez 24 godziny z zachowaniem wysokiej precyzji i pełnej powtarzalności wykonywanego zadania.

Dzięki specjalnej konstrukcji zapewniającej długoletnią, niezawodną prace w trudnych warunkach przemysłowych, roboty te zapewniają pewny i szybki wzrost z inwestycji. Podnoszą satysfakcję załogi, chroniąc od monotonnych i niebezpiecznych zadań. Pracownicy mogą się teraz skupić na pracy o wyższej wartości dodanej dla firmy.

Dzięki łatwości programowania, mobilności,

bogactwu dodatkowych akcesoriów,

roboty HCR podołają nieskończonej

ilości aplikacji, pracując wydajnie

przez 365 dni w roku.

Po skończonym zadaniu można

łatwo przemieścić robota HCR

na podstawie mobilnej, wymienić chwytak i rozpocząć kolejne zadanie.

Roboty HCR nie odpoczywają.

Po skończonym zadaniu

natychmiast zajmą się kolejnymi pracami, zwiększając efektywność twojej firmy.