Automatyzacja produkcji, robotyzacja procesów produkcyjnych

Jak zacząć robotyzację swojej firmy?

Zanim zaczniesz robotyzację, poczytaj nasze artykuły o robotyzacji, zobacz przykładowe wdrożenia automatyzacji linii montażowych, gniazd produkcyjnych czy maszyn dedykowanych do nietypowych operacji i procesów.

Automatyzacja w przemyśle (robotyzacja produkcji) - kompendium wiedzy

Wdrażać samodzielnie czy z Integratorem?

Zobacz jakie są różnice przy samodzielnym wdrożeniu a jakie gdy korzystasz z doświadczonego integratora.

Umów się na spotkanie o robotyzacji

Nasi Specjaliście porozmawiają w Tobą, wspólnie określą potrzeby twojej firmy i przedstawić rozwiązania.

Robot przemysłowy czy Cobot?

Przekonaj się sam, który rodzaj robota najlepiej pasuje do twojego charakteru produkcji i potrzeb.

Ile kosztuje wdrożenie robota?

Zobacz przykładowe koszty wdrożenia robota przemysłowego i cobota. Poznaj stopę zwrotu z inwestycji w robotyzację.

Zobacz jak robotyzują się inni

Poznaj filmy z wielu instalacji robotów przemysłowych i współpracujących w setkach firm. Zobacz jak w praktyce wygląda robotyzacja produkcji.

Robotyzacja z Integratorem

Poczytaj jak łatwo i szybko wdrożyć robota wspólnie korzystając z doświadczenia firmy integratorskiej.

Samodzielne wdrożenie robota

Dzięki bogatemu wsparciu technicznemu, możesz sam wdrożyć robotyzację w swojej firmie.

Szkolenia i kursy on-line z robotów

W łatwy i szybki sposób naucz się programować i wdrażać roboty. Nasi trenerzy podzielą się swoją wiedzą.

Poznaj bariery, które spowalniają robotyzację

Dzięki naszemu bogatemu doświadczeniu, poznasz tajniki udanych wdrożeń i efektywnie wprowdzisz robotyzację.

Zastosowanie automatyzacji w przemyśle

Dowiedz się więcej o typowych aplikacjach, gdzie roboty efektywnie wzmacniają konkurencyjność firm.

Robotyzacja produkcji - jak zacząć?

Wszyscy wiedzą, że coraz więcej Przedsiębiorstw wdraża rozwiązania związane z Industry 4.0. Technologie te poprawiają efektywność, wzmacniają konkurencyjność i zapewniają wysoką jakość wynikającą z precyzji i 100% powtarzalności jaką dostarczają roboty. Robotyzacja produkcji jest coraz powszechniejsza w wielu branżach. Często jednak słyszymy pytania od czego zacząć wdrażanie robotów i jak powinna wyglądać robotyzacja produkcji. Proponujemy kilka sprawdzonych rozwiązań by robotyzacja procesów stała się łatwa. Po pierwsze zobacz nasze e-booki przygotowane na podstawie wielu doświadczeń z licznych wdrożeń w różnych gałęziach przemysłu. Po drugie zachęcamy do kontaktu i zobaczenia robotów w działaniu, dodatkowo opowiemy o chwytakach, czujnikach, transporterach, stołach wibracyjnych, systemach wizyjnych i innych elementów, które powodują, że możliwa jest robotyzacja każdego rodzaju produkcji. Korzystając z naszych doświadczeń, sprawisz, że robotyzacja produkcji będzie efektywna, szybka i łatwa. Robotyzacja to wybór odpowiedniego robota przemysłowego, cobota i stołu wibracyjnego.

Samodzielnie czy z Integratorem?

Robotyzacja produkcji często stawia pytanie o samodzielnie budowanie kompetencji i integrację robota czy zaangażowanie do wdrożenia robota doświadczonej firmie integratorskiej. Nie ma w tym miejscu jednej dobrej odpowiedzi. Z punktu widzenia zarządzania ryzykiem, kompleksowa integracja stanowiska zrobotyzowanego daje nam bezpieczeństwo a Integrator pokrywa wszystkie ewentualne koszty związane z błędami w projekcie. Z drugiej strony jeżeli zdecydujemy się na samodzielną Integrację to budujemy wewnętrzne kompetencje w swojej organizacji, a zarazem obniżamy koszty wdrożenia robota. Warto jednak pamiętać, że Integrator wykonuje i koordynuje wszystkie istotne obszary niezbędne do zrealizowania swojego obszaru dostaw np. maszyny, linii produkcyjnej czy stanowiska zrobotyzowanego. Umiejscawiając funkcje Integratora na osi czasu, zaczynamy od koncepcji rozwiązania, później prace projektowe, kompletacja urządzeń, programowanie, montaż i uruchomienie, testy, osiągnięcie zakładanych wydajności i niezawodności aż po wieloletnią obsługę serwisową dostarczonych rozwiązań. W przypadku Integratora największą wartością dodaną dla Inwestora są kompetencje i doświadczenie z innych podobnych aplikacji. Niemniej ważną korzyścią jest mitygacja ryzyk związanych z projektem, których w każdym projekcie jest bardzo wiele a do ich minimalizacji przyczynia się doświadczenie w wielu zakładach i branżach oraz wynikające z tego doświadczenia i przewidywanie. Łatwo możemy przewidzieć rezultat, gdy robotyzacja produkcji robiona jest bez doświadczenia. Szczególnie ma to miejsce w przypadku projektów charakteryzujących się wiedzą ekspercką w zakresie np. spawania, polerowania lub lakierowania. Rekomendowałbym korzystanie z usług firm integratorskich w przypadku skomplikowanych procesów i projektów gdzie wymagane jest wiedza i doświadczenie.

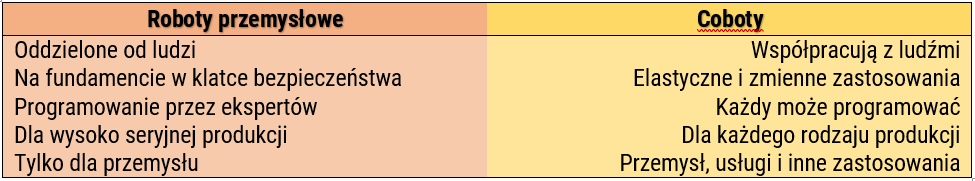

Automatyzacja i robotyzacja procesów produkcyjnych - bariery rozwojowe

Automatyzacja produkcji jest procesem, który ma na celu zoptymalizowanie procesu produkcyjnego a w efekcie wzrost efektywności. Historycznie rzecz ujmując, automatyzacja produkcji towarzyszy nam od wielu lat. Ostatnio jest szczególnie widoczna poprzez popularyzację robotyki. Jeszcze 50 lat temu robotyka zarezerwowana była dla dużych zakładów, głównie z branży automotive, które produkowały długie serie tych samych produktów. Dziś robotyka to wiele różnorodnych obszarów: roboty przemysłowe, roboty współpracujące tzw. coboty, roboty mobilne, roboty serwisowe. Szczególną rolę w powszechnej robotyzacji odgrywa dziś robot współpracujący. Jego olbrzymią zaletą jest to, że łatwo i szybko się programuje poprzez intuicyjne pokazywanie, co ma robić. Nie potrzeba już pisać złożonych algorytmów w skomplikowanych narzędziach programistycznych. Jak pokazuje praktyka, już kilkadziesiąt minut szkolenia pozwoli każdemu na zaprogramowanie prostych czynności na robocie HCR. Z kolei kilkugodzinne szkolenie, pozwoli skorzystać z zaawansowanych funkcji nowoczesnych Cobotów i połączenie ich z maszynami czy liniami produkcyjnymi. Coboty HCR zapewniają również możliwość bezpiecznej pracy z ludźmi. W razie nieplanowanego kontaktu z człowiekiem, Cobot po prostu się zatrzyma i wycofa. W efekcie nie potrzeba dla niego budowy klatek bezpieczeństwa, a w samym zakładzie zajmuje bardzo mało miejsca. Te cechy powodują, że jest elastycznym narzędziem nawet do krótko i średnioseryjnej produkcji w każdej wielkości zakładach produkcyjnych. Oczywiście wiele aplikacji wymaga wysokich prędkości lub przenoszenia ciężkich ładunków. W tych przypadkach stosujemy roboty przemysłowe, które po zastosowaniu wygrodzenia pracują tam, gdzie parametry robotów współpracujących są niewystarczające.

Zobacz nasze e-booki - automatyzacja przemysłu

Roboty współpracujące

FAKTY i MITY

Poczytaj broszurę , która pokazuje rolę i miejsce robotów współpracujących w nowoczesnych fabrykach

Roboty współpracujące

GDZIE I JAK WDRAŻAĆ?

Poznaj miejsca gdzie roboty współpracujące najlepiej się sprawdzają i gdzie wzmacniają efektywność produkcji.

Spawanie Cobotem

PRAKTYCZNY PORADNIK

Dowiedz się jak efektywnie wdrożyć spawanie Cobotem w twojej firmie, nawet w krótkich i średnich seriach produkcyjnych.

Roboty czy Coboty

CO WYBRAĆ?

Poznaj różnice pomiędzy robotami przemysłowymi a cobotami. Kiedy stosować roboty a kiedy coboty – poznaj odpowiedzi.

Umów się na spotkanie i testy - automatyzacja procesów produkcyjnych

Zapraszamy do kontaktu z naszymi Inżynierami, rozmowy i poznania specyfiki twoich procesów produkcyjnych. Połączymy wiedzę o procesie z naszą wiedzą o robotyce i doświadczeniami z wielu wdrożeń. Przygotujemy koncepcję robotyzacji odpowiadającą twoim potrzebom popartą wyliczeniami poszczególnych etapów procesu wraz ze szczegółową symulacją stopy zwrotu z inwestycji w robotyzację. Od teraz robotyzacja przemysłu może być łatwa i efektywna.

Zapraszamy do kontaktu

Skorzystaj z naszych szkoleń - robotyzacja produkcji

Zapraszamy do skorzystania ze szkoleń stacjonarnych i Akademii OnLine, gdzie poznasz jak łatwo automatyzacja i robotyzacja produkcji może być wdrożona w twojej firmie. Pokażemy wiele przykładów, zapoznamy Ciebie ze specyfiką. Dzięki bogatej ofercie szkoleniowej roboty współrpacujące nie będą miały żadnych tajemnic.

Szkolenia

Akademia OnLine

Dzięki łatwości programowania robotów współpracujących jest to możliwa jest samodzielna nauka programowania.

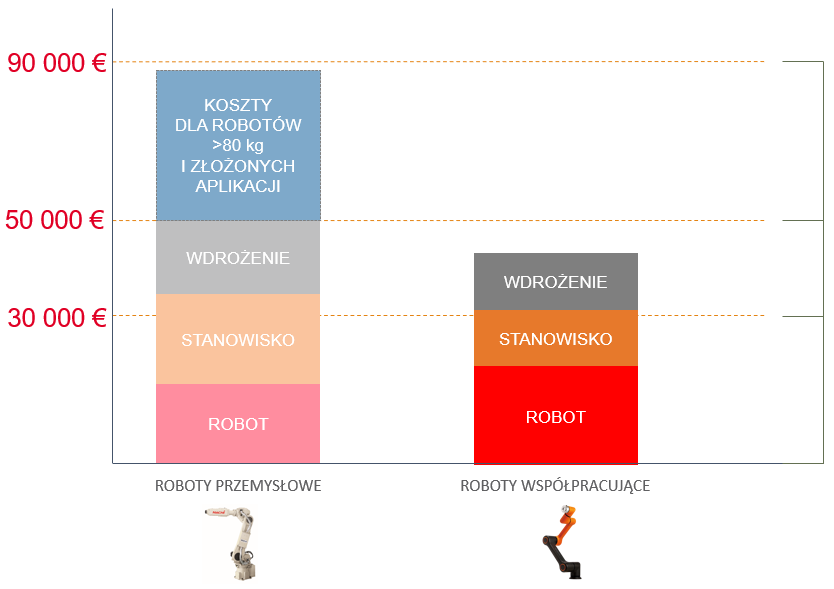

Automatyzacja produkcji - roboty współpracujące i przemysłowe - koszty

Koszt Cobota

Coboty są alternatywą dla robotów przemysłowych w miejscach gdzie nie są wymagane duże prędkości, zasięgi ramienia i udźwig. Automatyzacja produkcji w oparciu o roboty współpracujące dostarcza łatwe, szybkie, precyzyjne i wydajne narzędzie do wzmocnienia procesów produkcyjnych, które zwraca się średnio po 6 miesiącach przy pracy wielozmianowej. Coboty można wdrażać samodzielnie lub wspólnie z Integratorem. Koszt samodzielnego wdrożenia robota współpracującego to po prostu cena robota i chwytaka, a zaczyna się już od około 20.000 EUR za zestaw cobota o udźwigu 3 kg, a w przypadku udźwigu 12 kg koszt ten rośnie o około 60%.

Jeżeli zdecydujemy się na kompleksowe wdrożenie przez Integratora koszt rośnie o około 60-90%, ale uzyskujemy kompleksową usługę, indywidualny chwytak i mocowanie cobota, podajniki materiałów, integrację z transporterami lub maszynami oraz pełną dokumentację wdrożenia oraz projekt z certyfikacją bezpieczeństwa,

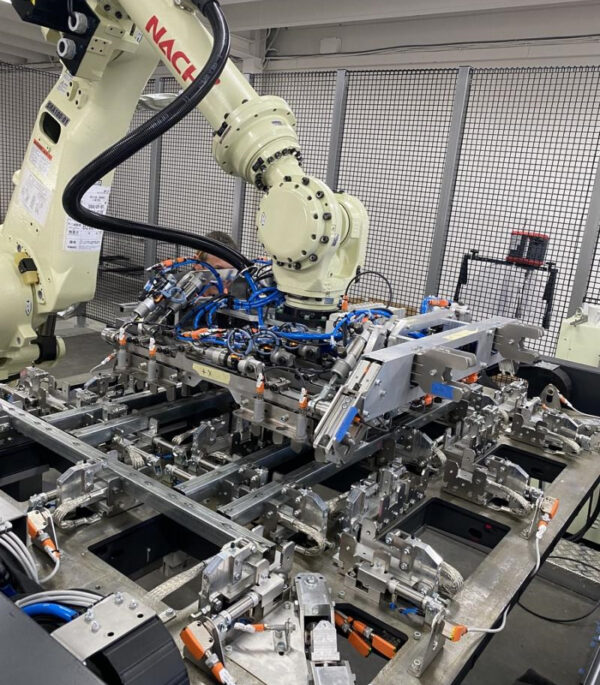

Koszt robota przemysłowego

Na koszt robota przemysłowego składają się poza ceną samego ramienia również bardziej zaawansowane programowanie, większa ilość zajmowanego miejsca i koszt klatek bezpieczeństwa. Niemniej jednak samo ramię jest w wielu przypadkach tańsze od cobota. Wysoka prędkość, udźwig i zasięg robotów przemysłowych powodują, że stosuje się je głównie w wysokoseryjnej produkcji gdzie istotny jest krótki czas cyklu.

Roboty przemysłowe wdraża się w oparciu firmy integratorskie lub samodzielnie w przypadku posiadania odpowiedniej kadry i doświadczenia. Koszty robotów przemysłowych zaczynają się już poniżej 10.000 EUR za roboty typu SCARA, a w przypadku robotów 6-osiowych już od niecałych 18.000 EUR. W przypadku kompleksowego wdrożenia przez firmę integratorską gdzie wykonywane są mocowania, klatki bezpieczeństwa, programowanie, chwytak, projekt, dokumentacja, szkolenie, certyfikacja CE koszt ten rośnie o około 80-100%.

Zwrot z inwestycji w robota / cobota

Szacuje się, że zwrot z inwestycji w lekkie roboty o udźwigu do 3 kg w przypadku gdy przedsiębiorstwo pracuje na 1 zmianę to około 12-14 miesięcy, przy pracy 2 zmianowej to już 9-11 miesięcy a przy pracy 24/7/365 to już poniżej 6 miesięcy.

W przypadku robota spawalniczego zwrot z inwestycji ROI, wygląda jeszcze atrakcyjniej. Przeciętnie spawacz jarzy łuk elektryczny przez 25-28% czasu pracy, w przypadku robotyzacji spawania jesteśmy w stanie osiągnąć czas jarzenia na poziomie 65-77%, co powoduje, że robot zastępuje 3 spawaczy.

Równie ciekawie wygląda robotyzacja paletyzacji, która w przypadku paletyzera o udźwigu 10-12 kg osiąga stopę zwrotu na poziomie 14 miesięcy przy pracy 3 zmianowej i około 11 miesięcy przy pracy 24/7/365. Zapraszam do kontaktu – precyzyjnie wyliczymy jakie oszczędności możesz osiągnąć robotyzując produkcję.

Podane obliczenia i kwoty są szacunkowe i nie stanowią oferty w rozumieniu kodeksu cywilnego.

Robotyzacja linii produkcyjnych - jak robią to inni?

Zobacz liczne filmy z wdrożeń robotów współpracujących, robotów przemysłowych i systemów podawania elementów dla robotów. Możesz lepiej poznać specyfikę pracy robotów, cobotów czy chwytaków korzystając z przykładów i zebranych doświadczeń.

Filmy referencyjne

Zastosowania

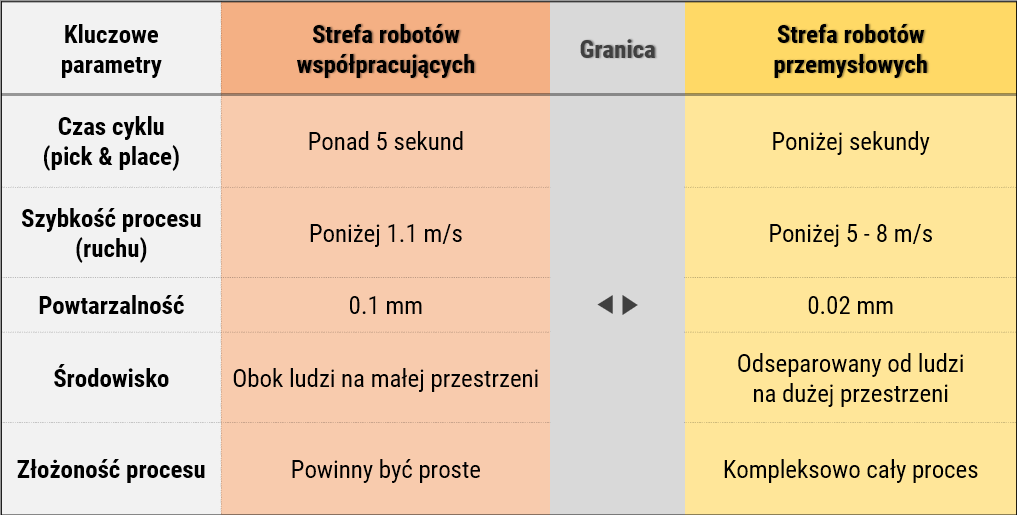

Robot przemysłowy czy współpracujący?

Często pojawiają się pytania czy stosować robota czy cobota. Oba rozwiązania się uzupełniają, choć na styku ich parametrów udźwigu czy zasięgu, może dochodzić do takich dylematów i pytań. Roboty współpracujące to stosunkowo nowe rozwiązanie, łatwe w programowaniu, lekkie, mogą bezpiecznie pracować z ludźmi zapewniając możliwość szybkich elastycznych zmian na produkcji. Natomiast roboty przemysłowe znane są już od ponad 60 lat. Charakteryzują się trudniejszym programowaniem, wymagają więcej miejsca i oddzielnie od ludzi wygrodzeniem, ale z drugiej strony są bardzo szybkie, mają duże udźwigi i zasięgi. W tym miejscu warto pokazać różnice w zakresie parametrów i podstawowych różnic.

Automatyzacja i robotyzacja - zastosowania

Roboty przemysłowe i współpracujące możemy używać niemal w dowolnych zastosowaniach. Poniżej pokazujemy typowe aplikacje, które wykorzystywane są w różnych gałęziach przemysłu.

Rozładunek i załadunek maszyn

Załadunek i rozładunek maszyn, podajników, opakowań, linii produkcyjnych, gniazd montażowych i obróbczych. Operacje załadunku i rozładunku mogą być realizowane na pojedynczym produkcie lub w przypadku potrzeby zwiększenia wydajności na pakiecie produktów ułożonych w powtarzalną formę geometryczną.

Robotyzacja przetwórstwa tworzyw sztucznych

Załadunek i rozładunek wtryskarek, odcinanie wlewów, kontrola jakości wyprasek w oparciu o ich masę i wzorce wizyjne, etykietowanie, pakowanie do opakowań zbiorczych. Robot doskonale sobie prowadzi automatyzacją i robotyzacją obsługi wtryskarek i z operacjami, które dotychczas wykonywali operatorzy, realizując je w dokładny i powtarzalny sposób przez 24/7/365.

Automatyzacja testów i kontroli jakości

Testy i kontrola jakości to czynności wymagające 100% powtarzalności i dokładności. Robotyzacja testów i kontroli jakości zapewnia wzrost efektywności i minimalizację błędów. Szczególnie istotne są testy międzyoperacyjne, kontrola finalnego produktu, co pozwala precyzyjnie kontrolować jakość. Każda czynność kontroli jest rejestrowana w systemie. A wszystko to w powtarzalny sposób.

Robotyzacja spawania - roboty spawalnicze

Spawanie od zawsze wymagało umiejętności, doświadczenia i precyzji. A pomimo tego spawanie jest bardzo wyczerpującym procesem i trudno jest zapewnić jakość i wydajność w dłuższym czasie pracy Operatora. Roboty na bazie których buduje się roboty spawalnicze i cele spawalnicze, zapewniają łatwość programowania ścieżek spawania z możliwością ich importu z oprogramowania CAD/CAM.

Robotyzacja polerowania - roboty polerskie

Polerowanie to proces wymagający precyzyjnego wyczucia siły i powtarzalności. Roboty wyposażone w czujniki siły doskonale sprawdzają się przy polerowaniu, szlifowaniu i obróbce powierzchniowej w wielu branżach. Robot przemysłowy korzystając z czujnika siły może dobierać pozycję i nachylenie narzędzia polerskiego zależnie od informacji otrzymywanych w osiach X/Y/Z a dodatkowe wykorzystanie systemu wizyjnego zapewnia możliwość wyboru obszarów do polerowania.

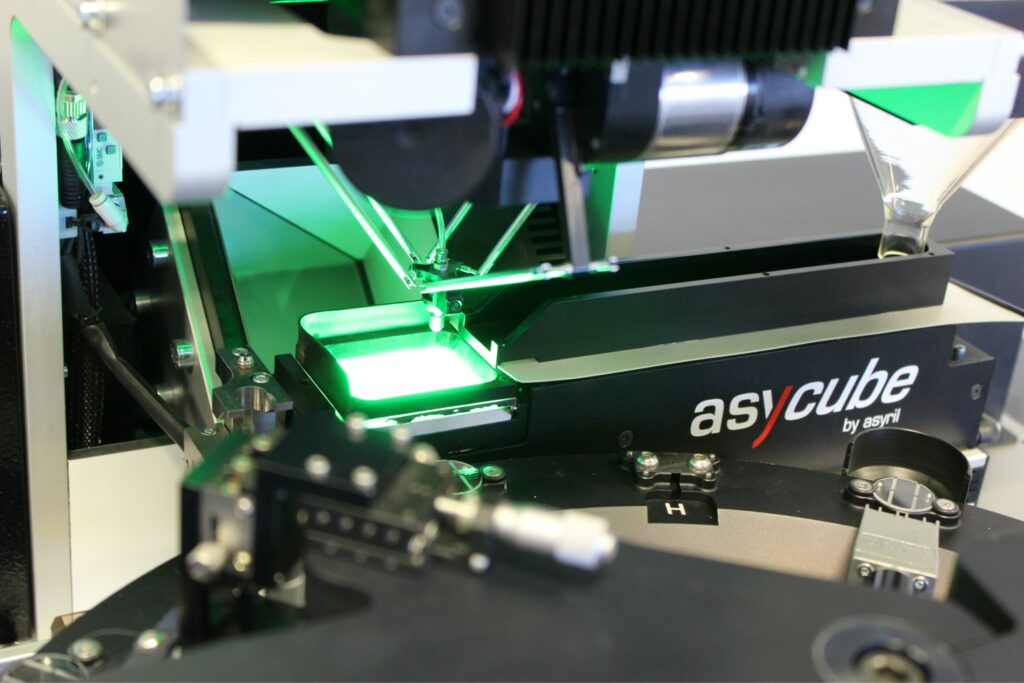

Automatyzacja w przemyśle elektronicznym

Obsługa PCB/ICT to prace związane z wysoką precyzją wynikająca z delikatnej natury części elektronicznych. Dotychczas robotyzacja była dostępna dla dużych i powtarzalnych serii. Roboty współpracujące zapewniają robotyzację już w małych i średnich seriach. A wszystko to dzięki elastyczności i łatwemu programowaniu, co jest szczególnie ważne w robotyzacji przemysłu elektronicznego i dostawców EMS.

Robotyzacja paletyzacji - paletyzery

Paletyzacja to monotonna czynność, która powoduje uszczerbek na zdrowiu. U jednego z naszych Klientów policzyliśmy, że w ciągu doby, Pracownicy przeładowują aż 80 ton produktów, pracując w mało ergonomicznych pozycjach. Zastosowanie cobotów pozwala na efektywną i elastyczną paletyzację zmiennych partii produkcyjnych. Od teraz roboty paletyzujące i paletyzery oparte na robotach współpracujących HCR są dostępne dla każdej wielkości przedsiębiorstwa.

Robotyzacja pakowania

Pakowanie, miksowanie produktów, zestawy promocyjne to powtarzalna czynność, która wymaga częstych zmian. W branży tej spotyka się często spiętrzenia produkcyjne, zwłaszcza w wysokich sezonach zakupowych. Rozwiązaniem na problem sprostanie wymaganiom rynku są roboty współpracujące, które dokładnie i efektywnie mogą pakować dowolne produkty na linii produkcyjnej lub w gniazdach produkcyjnych. Od teraz roboty pakujące i oparte na robotach współpracujących maszyny pakujące są dostępne dla każdej wielkości produkcji.

Robotyzacja obsługi maszyn - automatyzacja CNC

Obsługa maszyn to jedno z podstawowych zastosowań Cobotów. Mając na uwadze chwytaki, które adaptują się do wielu kształtów można samodzielnie w ciągu kilkunastu minut nauczyć robota rozładunku i załadunku maszyny. Nie ma tu znaczenia czy mówimy tu o robotyzacji obsługi maszyn, automatyzacji maszyn CNC, pras hydraulicznych, wykrawarek, pras rewolwerowych, tokarek, frezarek czy drążarek.

Robotyzacja obróbki metalu

Obsługa obróbki metalu to proces wymagający wytrzymałych i dokładnych narzędzi. Taki jest robot przemysłowy i współpracujący HCR, które posiada całkowicie metalową obudowę i przystosowany jest do pracy ciągłej w trudnych warunkach. W ramach obróbki metalu możemy zrobotyzować procesy nitowania, wiercenia, przykręcania, obróbki powierzchniowej, załadunku maszyn, linii i gniazd produkcyjnych.

Robotyzacja montażu

Montaż to czynność wymagająca z jednej strony precyzji a z drugiej podatna na rutynę wynikająca ze zmęczenia Pracowników. Roboty i coboty są doskonałym narzędziem do automatyzacji montażu i robotyzacji linii produkcyjnych. Zapewniają możliwość wykonywania robotyzacji przykręcania, automatyzacji zatrzaskiwania, obsługi etykieciarek, pakowania, znakowania, testowania na stanowisku pracy i wielu innych czynności montażowych.

Robotyzacja malowania i klejenia

Malowanie i klejenie to procesy związane z trudnymi warunkami i potrzebą zapewnienia precyzyjnego dozowania substancji chemicznych. Robot z dyszą dozującą pozwala w pełni zoptymalizować zużycie środków chemicznych a dodatkowo uwolnienie ludzi od pracy w trudnych warunkach. Nie bez znaczenia jest w pełni powtarzalny wynik pracy w postaci wysokiej jakości powłok. Robotyzacja klejenia, automatyzacja malowania staje łatwa i szybka we wdrożeniu nawet w krótkich seriach.

Robotyzacja badań i laboratoriów

Robotyzacja laboratoriów, automatyzacja obsługi próbek i badań pozwala precyzyjnie umieszczać badany materiał w maszynach, testerach, spektrometrach czy analizatorach. Każda próbka może być etykietowana, kody z etykiet są odczytywane i rejestrowane w systemie. A wszystko to w powtarzalny sposób. Niektóre z naszych robotów i cobotów posiadają certyfikację Cleanroom class 2, co pozwala im pracować w szczególnie wymagających warunkach czystych pomieszczeń.

Zalety automatyzacji

Automatyzacja i robotyzacja linii produkcyjnych, wdrażanie zautomatyzowanych gniazd produkcyjnych zwiększa efektywność i jakość produkcji. Robotyzacja zapewnia automatyzację szeregu czynności począwszy od przenoszenia, transportu, montażu, znakowania, pakowania i kontroli jakości. Istotnym wynikiem automatyzacji jest wysoka jakość i powtarzalność procesów. Warto wspomnieć o wzroście wydajności wynikającym z pracy 24/7/365. Roboty mogą wspomagać firmy przy monotonnych, wyczerpujących, powtarzalnych i często niebezpiecznych pracach, które wymagają skupienia i obciążają Operatorów. Dzięki robotyzacji eliminujemy ryzyko błędów ludzkich, które oddziałuje na bezpieczeństwo pracy i jakość produktów. Przemysłowe roboty współpracujące mogą być wyposażone w dowolne narzędzie do realizacji różnorodnych procesów produkcyjnych. Dodatkowo roboty współpracujące dzięki wbudowanym funkcjom bezpieczeństwa mogą pracować obok ludzi na małej powierzchni bez potrzeby zmian w układzie produkcyjnym. To ogromna zaleta przy robotyzacji istniejących fabryk i procesów. Mając na uwadze globalne trendy należy stwierdzić, że automatyzacja linii produkcyjnych i robotyzacja przemysłu jest dziś koniecznością dla każdej wielkości przedsiębiorstw.

Roboty przemysłowe - korzyści

- Kontrola kosztów produkcji niezależnie od zmian na rynku pracy

- Stabilna wydajność

- Powtarzalność procesów

- Wysoka jakość i precyzja

- Optymalizacja zużycia materiałów w wyniku minimalizacji odpadów

- Bezpieczna praca w trudnych warunkach środowiskowych

- Ochrona zdrowia Pracowników

- Integracja maszyn i urządzeń w systemy produkcyjne

- Kontrola operacji i wydajności

Automatyzacja i robotyzacja z Integratorem

KROK 1 - Automatyzacja procesów produkcji – Jaki mam cel?

Automatyzacja i robotyzacja procesów produkcyjnych wymaga precyzyjnego określenia celu. W tym miejscu pojawia się wiele wątpliwości co nam przyniesie robotyzacja procesów przemysłowych. Dlatego polecamy określenie precyzyjnych celów jakie robotyzacja produkcji ma nam zapewnić. W większości projektów, które realizujemy pojawiają się następujące potrzeby jakie ma dostarczać automatyzacja produkcji:

- Zwiększenie wydajności poprzez eliminację przerw, mikro przestojów w wyniku czego osiągamy wykorzystanie maszyn i budowli przez 24 godziny.

- Zwiększenie wydajności poprzez skrócenie czasu cyklu wynikającego z szybkości robotów przemysłowych.

- Zmniejszenie kosztów produkcji wobec rosnących wynagrodzeń.

- Zabezpieczenie przedsiębiorstwa przed brakiem pracowników wynikającym z globalnych trendów starzenia się społeczeństw w państwach wysoko uprzemysłowionych.

- Minimalizacja ryzyka wypadków przy pracy, wynikających z wykonywania monotonnych czynności i pracy w niebezpiecznych warunkach przy oparach klejów, farb, gorących i ostrych częściach maszyn, zapyleniu w wielu innych.

- Eliminacja kosztów utraty jakości, które pojawiają się wobec pojawiających się błędów przy wykonywaniu rutynowych czynności, zmęczenia, zmiennych kompetencji w wyniku rotacji pracowników.

KROK 2 - Automatyzacja przemysłu - znajdź właściwa aplikację

Automatyzacja procesów produkcyjnych wymaga znalezienia odpowiednich miejsc dla robotów. W tym miejscu dochodzi do kluczowego dla całego procesu połączenia wiedzy o procesie produkcyjnym w danym przedsiębiorstwie i wiedzy o technologii jaką posiada Integrator lub dostawca technologii robotycznej. Tylko przy właściwym zrozumieniu potrzeb i możliwości jakie niesie robotyzacja procesów produkcyjnych, możemy wypracować efektywne rozwiązania. Zdecydowanie rekomenduję by automatyzacja i robotyzacja była wprowadzana w obszarach, gdzie są łatwe czynności, zapewniające szybkie wdrożenie i atrakcyjną stopę zwrotu z inwestycji. Niejednokrotnie stawiane są wymagania by robotyka i automatyzacja procesów pozwalały automatyzować skomplikowane, wieloetapowe czynności o małej powtarzalności a do tego wymagające angażowania wielu dodatkowych elementów kontrolnych. W większości takich przypadków pojawia się podobna odpowiedź, technicznie to możliwe do zrealizowania ale niestety stopa zwrotu będzie zbyt długa by projekt był opłacalny. Na dzień dzisiejszy czynności które najczęściej obejmuje robotyzacja produkcji to: paletyzacja, spawanie, załadunek i rozładunek maszyn, pakowanie, montaż, polerowanie, malowanie i wiele innych.

KROK 3 - Robotyzacja procesów produkcyjnych - koncepcja

Gdy już wiemy co i dlaczego chcemy zrobotyzować, pojawia się potrzeba wstępnej koncepcji. Nasi specjaliści dla których robotyzacja procesów przemysłowych nie ma tajemnic przygotują szczegółowy opis rozwiązanie, zestawienie elementów, czasy buforów na materiał i produkt gotowy, rozwiązania w zakresie bezpieczeństwa stanowiska, ergonomię stanowiska i drogi transportowe z przepływem materiałów, wizualizację stanowiska, obliczenia wydajności, harmonogram wdrożenia i szczegółowe wymagania towarzyszące. W CoRobotics preferujemy partnerską pracę z Klientem przy opracowywaniu koncepcji, by nie pominąć żadnych istotnych wymagań, które w późniejszym etapie mogłyby utrudniać efektywną realizację projektu.

KROK 4 - Kontraktacja i realizacja projektu robotyzacji procesów produkcyjnych

Gdy już wiemy co, dlaczego, jak chcemy realizować projekt, automatyzacja produkcji startuje na etapie wdrożeniowym i rozpoczyna się etap uszczegóławiania koncepcji by finalnie stworzyć projekt stanowiska. Następnie Integrator współpracujący z CoRobotics dokonuje kompletacji elementów i montażu. W następnej kolejności powstaje gotowe stanowisko w firmie Integratorskiej, po czym poddawane jest próbom wydajności, bezpieczeństwa w zakresie na jaki pozwala miejsce instalacji u Integratora i nieobecność linii/maszyn związanych ze stanowiskiem. Po spełnieniu wymagań przewidzianych kontraktem, dokonywany jest odbiór fabryczny FAT [factory acceptance tests] w obecności Klienta, CoRobotics jako dostawcy technologii i Integratora CoRobotics. Po testach w zależności czy pojawiły się potrzeby działań korygujących, uzgadniany jest szczegółowy harmonogram godzinowy instalacji na miejscu docelowym. Po zmontowaniu na miejscu docelowym prowadzony jest ruch próbny stanowiska w celu regulacji, sprawdzenia i osiągnięcia zakontraktowanych wydajności. Po potwierdzeniu kluczowych parametrów dokonywane jest szkolenie z obsługi stanowiska. Na końcu przeprowadzany jest odbiór końcowy SAT [site acceptance tests] w czasie którego przekazywana jest dokumentacja, stanowisko, deklaracji CE dla stanowiska oraz wspólnie potwierdzane jest spełnienie wymagań kontraktowych.

Samodzielna automatyzacja procesów produkcyjnych

KROK 1 - Robotyzacja procesów produkcyjnych – Jaki mam cel?

Automatyzacja produkcji ale też wiele innych działań mają wspólny mianownik, którym jest precyzyjne określenie celu. Automatyzacja produkcji, którą nasi Klienci planują wdrażać samodzielnie, ma odpowiadać na następujące potrzeby:

- Zwiększenie wydajności poprzez przyśpieszenie procesu, eliminację przerw i możliwość pracy 24 godziny na dobę przez roboty.

- Eliminacja problemu rosnących kosztów wynagrodzeń.

- Minimalizacja nieobecności i rotacji pracowników

- Minimalizacja wypadków przy pracy, wynikających z powtarzalnych czynności oraz niebezpiecznych warunków np. kleje, farby, gorące i ostre części maszyn, zapylenie i wiele innych.

- Podniesienie jakości w oparciu o 100% powtarzalność i dokładność jakie daje robotyzacja procesów przemysłowych

KROK 2 - Automatyzacja procesów produkcji - właściwa aplikacja, robot i osprzęt

W czasie spotkania z naszymi Inżynierami ds. aplikacji i wdrożeń dokonujemy analizy aplikacji, dobieramy odpowiedni sprzęt w postaci robota, chwytaka, systemu wizyjnego, stołu lub podestu. Ustalamy dokładny zakres dostaw i usług. Najczęściej wybieraną formułą są pakiety szkolenia, podłączenia i uruchomieniem, programowania i asysty przy wdrożeniu. Takie pakiety trwają od 1 do 4 dni w zależności od złożoności aplikacji i potrzeby podłączania urządzeń zewnętrznych.

KROK 3 – Realizacja projektu - automatyzacja procesów produkcyjnych

Gdy już wiemy co, dlaczego, jak chcemy zrobotyzować, pojawia się u Państwa w Zakładzie nasz Inżynier aplikacji i wdrożeń, który dostarcza sprzęt, montuje go, podłącza, uruchamia i programuje, wspólnie z Państwa Pracownikami. Następnie dokonywane jest szkolenie z obsługi stanowiska. Na końcu przeprowadzany jest odbiór końcowy SAT [site acceptance tests] w czasie którego potwierdzane jest spełnienie wymagań kontraktowych.