HCR-3A is lightweight robot with 3 kg payload and 630 mm reach, dedicated for pick & place, line assembly of light elements on the limited spaces. Infinite 6th joint rotation is perfect for screwing.

Number of Axis

6

Reach

630 mm

Repeatability

0.05 mm

Payload

3 kg

Footprint

Ø 130 mm

6th Axis rotation

infinite

Technical Data - HCR-3A Arm

Payload

3 kg

Reach

630 mm

Number of Axis

6

Tool speed

1 m/s

Weight

13 kg

Repeatability

±0,05 mm

Working conditions

IP 64

Operating temperature

0-50°C

Controller cable lenght

6 m [option 10 m]

Arm design material

aluminium – steel

EOAT connection type

2 x M8 | 8-pin + EtherCAT

EOAT mounting

ISO9409-1-50-4-M6

Digital inputs

2

Digital outputs

2

Analog inputs

2

Certifications

EN ISO13849-1, Cat 3, PLd, EN ISO 10218-1, CE MD, KCs

Joint range

J1: ±360° J2: ±360°

J3: ±160° J4: ±360°

J5: ±360° J6: Infinite

Lifetime

35 000 h

Technical Data - Teach Pendant - Pilot uczenia

Dimensions

340x268x81 mm

Weight

1.8 kg

Display

12″, 1024×768,

resistant touch

User interface

GUI, Buttons: Power,

Emergency Switch

Cable length

5 m

Accesories

T/P holder

Operating temperature

0-50°C

T/P housing material

plastic

Technical data - controller

Dimensions

450x470x223 mm

Weight

17.6 kg

Communication

TCP/IP, EtherCAT,

Modbus TCP

option: EthernetIP, Profinet

Force detection range

25-150 Nm

Inputs / Outputs

16 digital inputs [PNP]

16 digital outputs [PNP,

max.200 mA]

Analog: 2 inputs, 2 outputs

Power supply

100-240 VAC, 50-60 Hz

Operating temperature

0-50°C

Controller design material

painted zinc stell

Noise level

≤ 60 dB

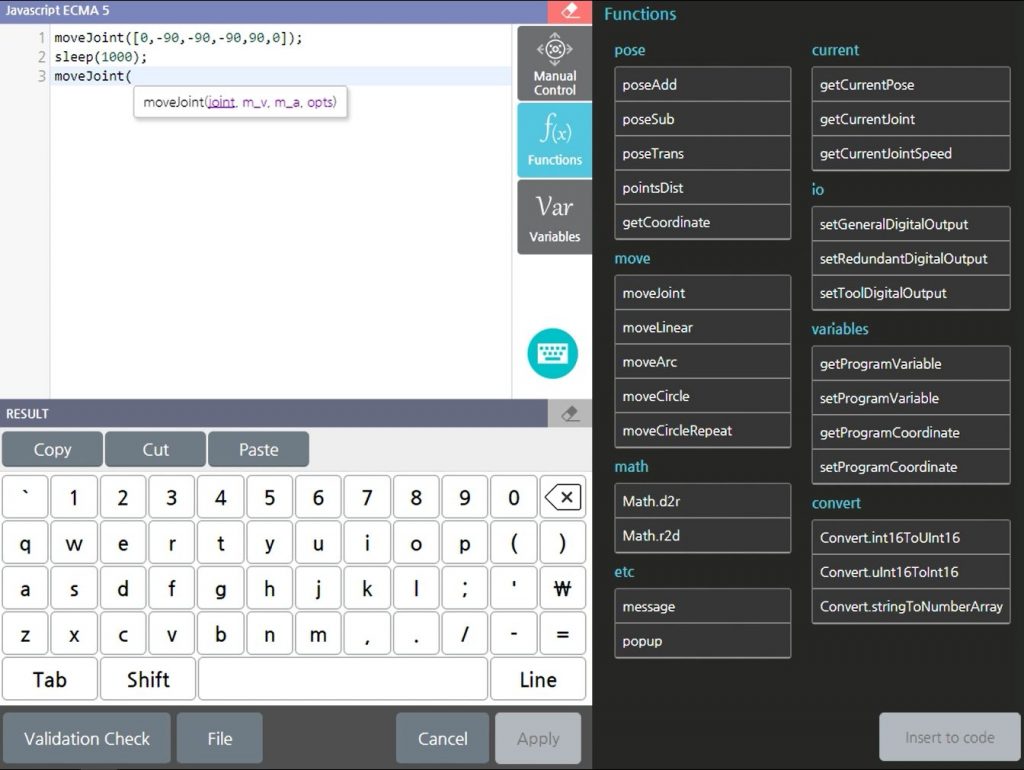

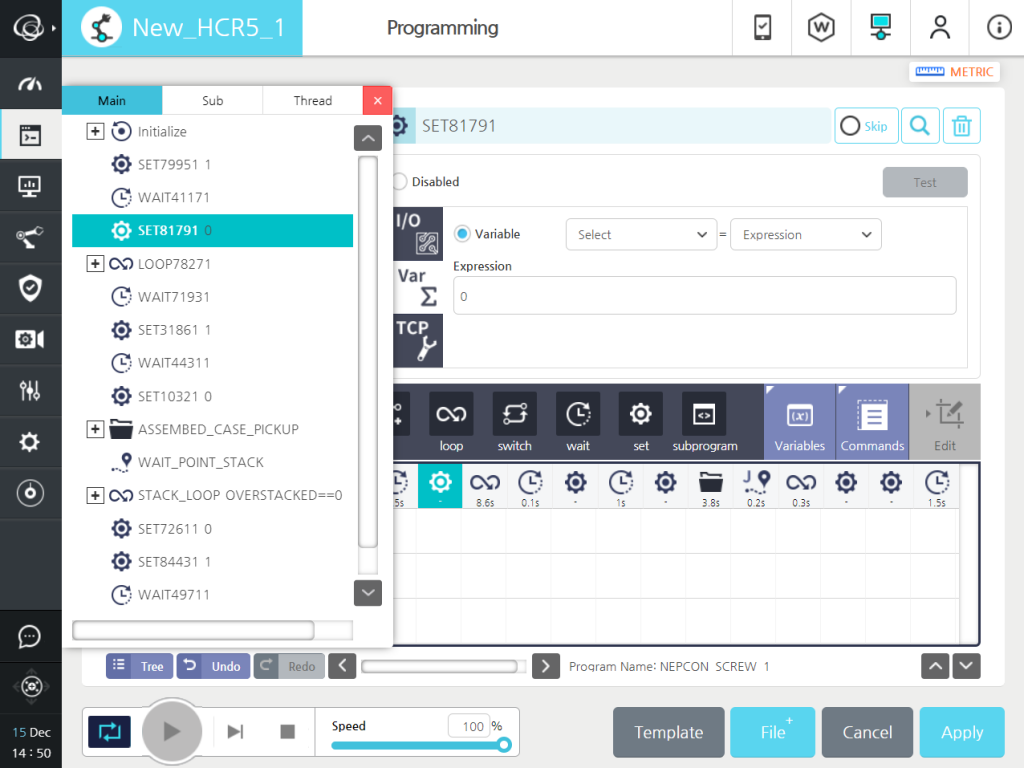

RODI software

Intuitive RODI software with a graphical user interface allows you to easily operate the HCR robot. Using traditional industrial robots required programming knowledge and multi-week training. The RODI software allows you to easily and intuitively program people without expert knowledge. In order to program it is enough to put appropriate icons on the timeline, use ready-made templates or programs.

RODI benefits

- Intuitive graphical user interface

- Friendly icons placed chronologically on the axis

- Ready templates of the most used functions

- Ready programs

- Easy integration with external devices

- Ready base of Plug’n’Play devices

3D visualization - step by step

Build your own programs using scripts

Intuitive interface with time-axis

Applications

HCR collaborative robots, work continuously 24/7/365 performing tasks in difficult industrial conditions. They ensure 100% repeatability, accuracy of work. Numerous applications in the country and abroad confirm the rapid return on investment in the HCR robot. The robot, due to its flexibility of application and the speed of implementation, returns already in 6 months and we meet an application where the return takes place after 2 months. These are cases where the precision of the robot allows to minimize material losses and eliminate costly quality errors.

After removing the HCR robot from the box, it takes just an hour to start and program the first task. HCR robots are equipped with an intuitive graphical user interface in 3D, which allows you to program the robot after several dozen minutes of learning. In a simple way we can show what the robot has to do – by moving its arm from point to point, we can write complicated motion paths by showing what is particularly useful in applications requiring complex movements. The robot’s implementation has never been so fast and easy.

HCR robots are designed for hard continuous operation in industrial conditions. They work persistently for 24 hours with high precision and full repeatability of the task. Thanks to the special construction that ensures long-term, reliable work in difficult industrial conditions, these robots provide a confident and rapid increase in investment. They increase the crew’s satisfaction, protecting them from monotonous and dangerous tasks. Employees can now focus on work with higher value added for the company.

Thanks to the ease of programming, mobility, a wealth of additional accessories, HCR robots will cope with the infinite number of applications, working efficiently 365 days a year. After the finished task can be it’s easy to move the HCR robot on the mobile basis, change the gripper and start another task. HCR robots do not rest. After finishing the task they will immediately deal with further work, increasing the efficiency of your company.