Paletyzer, Roboty paletyzujące, Robotyzacja paletyzacji

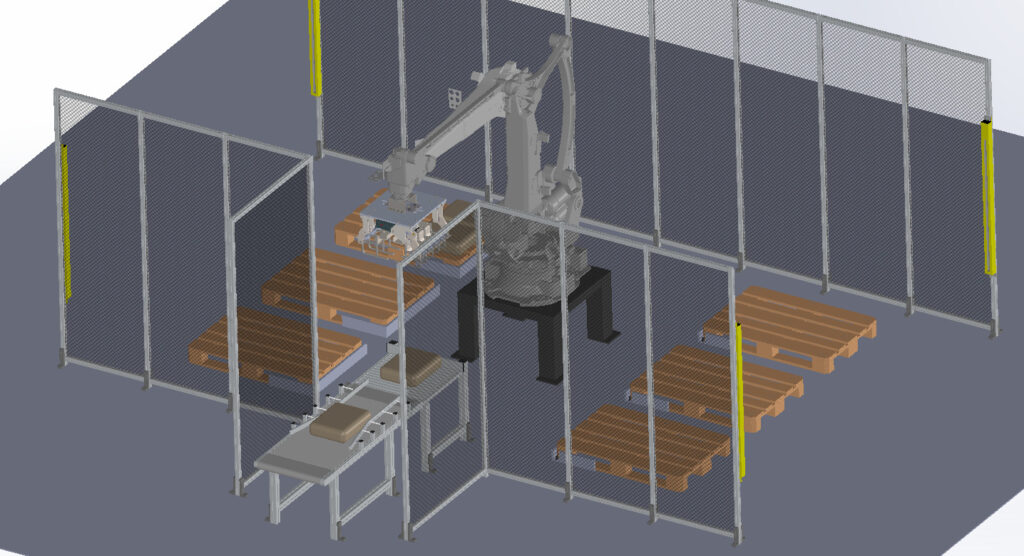

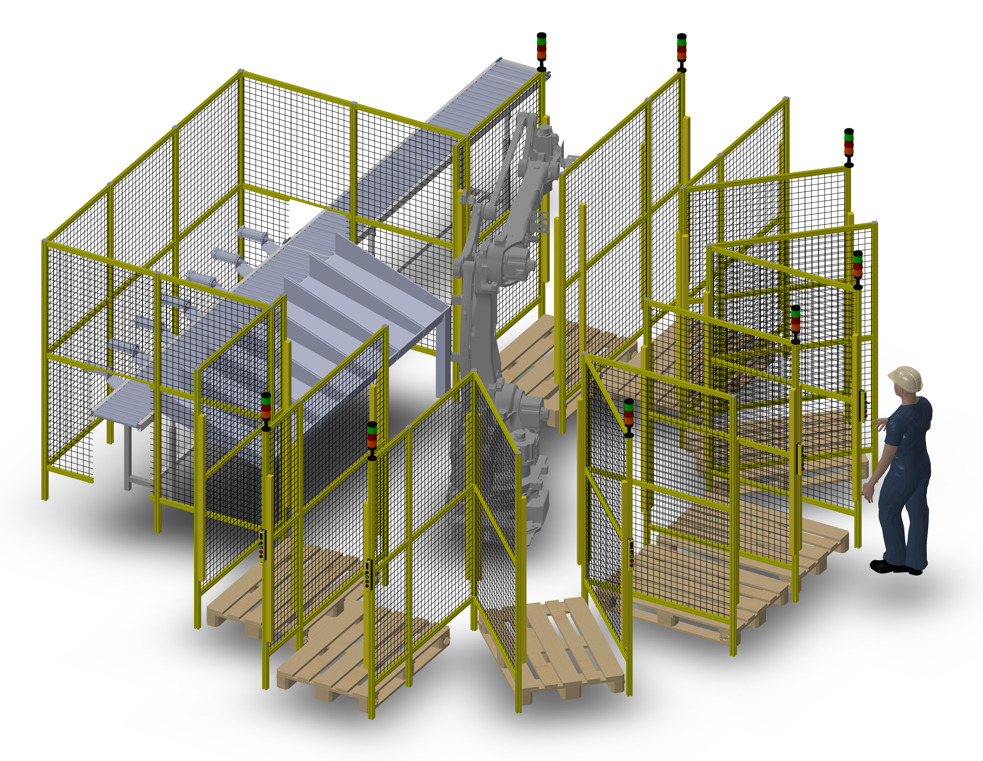

Zobacz nasze rozwiązania do paletyzacji. Niezależnie czy poszukujesz stanowiska do układania kartonów na palecie, całych warstw puszek farby lub słoików czy ciężkich worków z materiałami sypkimi to nasze rozwiązania idealnie pasują do twoich potrzeb. Każde stanowisko konfigurujemy idealnie pod twoje potrzeby. Możemy zastosować systemy podawania pustych palet, bufor na kilka pełnych palet, automatyczny transport palet w oparciu o rozwiązania AGV/AMR. Owijanie palet, etykietowania, kontrola wagi? Powidz nam jakiej funkcjonalności potrzebujesz, a my dostarczymy optymalne rozwiązanie.

Robotyzacja paletyzacji wzmacnia konkurencyjność twojej firmy

- Wzrost efektywności produkcji

- Wysoka wydajność

- Dostosowanie do indywidualnych potrzeb

- Niskie koszty operacyjne

- Elastyczność na zamiany na linii

- Oszczędności kosztowe

- Wysoka wydajność

- Precyzja działania

- Wysoka niezawodność

- Łatwa i intuicyjna obsługa dedykowanym interfejsem graficznym

Dlaczego paletyzacja robotem?

- Dowolne schematy paletyzacji

- Magazynki pustych palet z systemem automatycznej wymiany palety

- Opcjonalne etykietowanie, owijanie palet folią, klejenie warstw hot-melt czy kontrola produktu systemem wizyjnym i/lub wagą przepływową

- 100% powtarzalna jakość

- Bezpieczeństwo dla personelu

- Przekazywanie danych w czasie rzeczywistym

- Intuicyjne oprogramowanie do łatwego programowania nowych schematów paletyzacji i produktów

Robot paletyzujący

Do paletyzacji wykorzystujemy roboty zarówno typowo dedykowane modele serii LP, czyli szybkie 4-ro osiowe maszyny o dużym zasięgu roboczym, ale również modele 6-cio osiowe serii MZ, MC, SRA, które dzięki większej ilości osi pozwalają operować w ciasnych przestrzeniach oraz wykonywać dodatkowe operacje z manipulowanym ładunkiem. Z zadaniach gdzie nie jest wymagana wysoka prędkość i udźwig stosujemy roboty współpracujące HCR, które pozwalają na szybkie wdrożenie paletyzacji na końcu dowolnej linii.

Paletyzacja to jedno z najbardziej uciążliwych czynności produkcyjnych

W wielu przypadkach manualna paletyzacja to miejsce w którym powstają tzw. „wąskie gardła” i wynikające z nich straty w procesie produkcyjnym. Właśnie dlatego coraz częściej wiele zakładów decyduje się na robotyzację tego procesu. Dzięki elastyczności obecnych technologii robotycznych, nie ma znaczenia czy obsługujemy jeden rodzaj produktu czy elementy o różnej masie, kształcie czy materiale. Roboty przemysłowe lub coboty zapewniają w każdym przypadku wysoka wydajność, jakość co skutkuje poprawą efektywności procesów produkcyjnych.

Paletyzacja jest czynnością związaną z przenoszeniem ciężkich ładunków w nieergonomicznych pozycjach, dlatego też jej robotyzacja pozwala uchronić Pracowników od licznych chorób zawodowych związanych z tym procesem. Niejednokrotnie paletyzacja wykonywana jest w otoczeniu narażonym na hałas, zapylenie czy w otoczeniu ruchomych części maszyn. Robotyzacja rozwiązuje te wszystkie problemy, zapewniając niższe koszty operacyjne niż manualnie wykonywany proces.

Dlacego warto automatyzować paletyzację?

Najwyższe standardy

Zastosowanie robotów przy paletyzacji zapewni spełnienie najwyższych standardów precyzji, jakości i powtarzalności

Oszczędność miejsca

Roboty mogą na jednej zoptymalizowanej przestrzeni wykonywać różne czynności np. znakowanie, oklejanie, foliowanie, itp. Dedykowane magazynki palet będą automatycznie dostarczać wolne palety na stanowisko, roboty mobilne będą odwozić do magazynu gotowe załadowane palety.

Wysoka powtarzalność

Roboty zapewniają precyzję działania i powtarzalność procesu, co przekłada się na wysoką jakość. Nawet przy paletach, których wysokość osiąga do 2 m wysokości, uzskanie dokłądności ułożenia produktów na poziomie 1 mm, nie stanowi problemu.

Wydajność w każdych warunkach

Roboty zapewniają dużą szybkość działania, co przekłada się na efektywność. Linie i roboty paletyzujące pozwalają pracować w dowolnym środowisku. Nie ma tu znaczenia czy mówimy o hałasie, zapyleniu, niskich temperaturach

Dużo powtarzalnych towarów

Roboty doskonale się sprawdzą w szybkim i precyzyjnym ułożeniu dużych ilości towarów na paletach. Krótki czas cyklu nie stanowi tu żadnego problemu. Roboty do paletyzacji NACHI doskonale poradzą sobie w tym zadaniem.

Elastyczne rozwiązania paletyzacji

Oprogramowanie do paletyzacji pozwala programować wiele schematów paletyzacji i obsługę kilkunastu rodzajów opakowań jednocześnie. Stanowisko może automatycznie dostosowywać się do danych z zewnętrznych systemów IT lub być łatwo programowane przez dowolnego Pracownika.

Nasze linie i roboty do paletyzacji obsługują dowolne opakowania, kształty i masy

Nasze rozwiązania do paletyzacji mogą przenosić i układac dowolne opakowania. Niezależnie czy mówimy tu o materiałach sypkich, płynnych w pojemnikach, stałych w kartonach czy wielu innych.

Kartony

Pojemniki wiaderka

Zgrzewki i pakiety

Worki

Butelki

Torebki

Jak pracujemy z projektem paletyzacji?

Na początku wspólnie określamy twoje wymagania w zakresie wydajności, rodzaju materiałów, środowiska pracy, ilości miejsca i pełnej specyfikacji paletyzacji. Niezależnie czy potrzebne są przekładki, klejenie, foliowanie, znakowanie, etykietowanie lub nadruk oznaczeń, przygotowujemy szczegółową specyfikację i wizualizacje procesu, byś mógł zobaczyć jak będzie wyglądać stanowisko. Nasi eksperci na podstawie bogatych doświadczeń z wielu projektów, przeprowadzą Ciebie przez cały projekt, krok po kroku rekomendując optymalne rozwiązania.

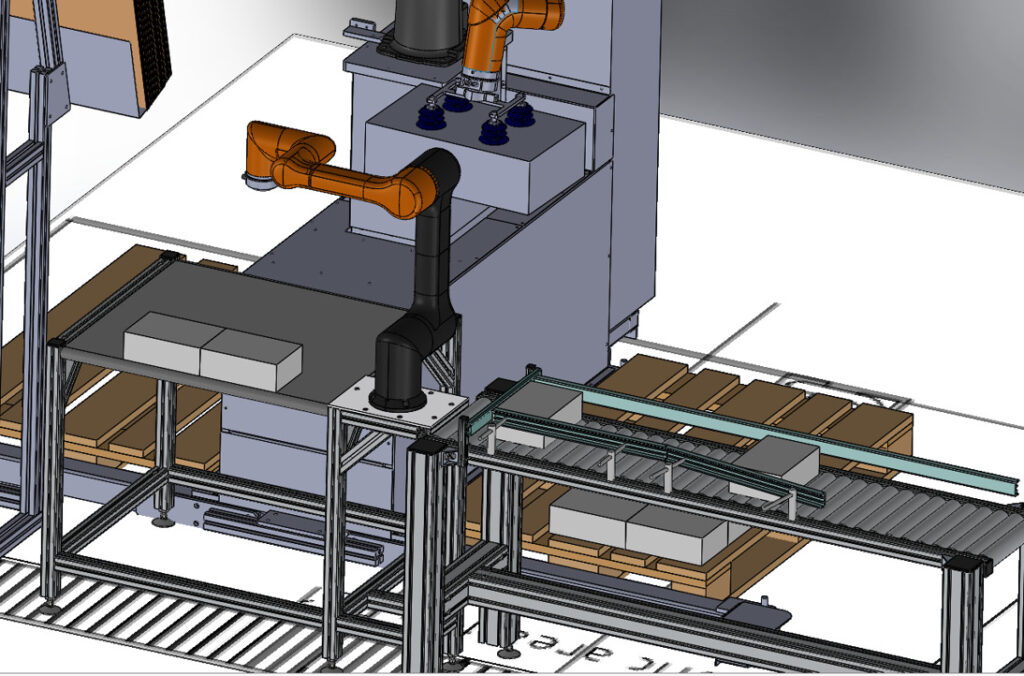

Przed rozpoczęciem projektu dostajesz kompletną koncepcję z policzonymi wydajnościami, layoutem przestrzeni produkcyjnej, drogami transportowymi, symulacją pracy, sprawdzeniem funkcjonalności oraz szczegółowym wykazem dostaw i usług wdrożeniowych.

Po pierwsze symulacja twojego stanowiska paletyzacji

Każdy projekt paletyzacji poprzedzamy wykonaniem symulacji pod kątem zasięgów robota, wysokości układania warstw na palecie czy odległości pomiędzy poszczególnymi komponentami stanowiska jak końcówka linii, miejsca paletowe czy magazyn palet. Do tego sprawdzamy czas cyklu, czy stanowisko osiągnie wymaganą wydajność. Zobacz kilka przykładowych symulacji, które poprzedzają każdy realizowany przez nas projekt.

Paletyzacja robotem - podstawowe funkcje

- Kontrola tolerancji wymiarów i masy opakowań z automatyczną eliminacją produktów niespełniających parametrów

- Znakowanie, nadruk, etykietowanie produktów jednostkowych i opakowań zbiorczych

- Formowanie kartonów, podstawek, kształtek transportowych i pakowanie

- Formowanie worków wraz z zasypywaniem zawartością i zamykaniem

- Zamykanie opakowań i kontrola jakość zamknięcia

- Obsługa przekładek, narożników i kątowników ochronnych na palety

- Kontrola zgodności opakowań z wzorcem danych lub danymi z systemu IT

- Pakowanie zestawów różnych produktów w opakowaniach zbiorczych tzw. product mix

- obsługa typowych palet przemysłowych, EUR palet do wysokości 2,75 m

- gotowe schematy paletyzacji – wielowarstwowe ze zmiennymi schematami paletyzacji na poszczególnych warstwach

- lokalizowanie, pobieranie, układanie według określonego wzorca

- możliwość programowania różnych schematów paletyzacji dla poszczególnych warstw

- integracja z liniami, transporterami – kontrola ruchu transportera, występowania opakowań do paletyzacji

- układanie i pobieranie według zadanych wzorców z kontrolą warstw i przekładek

- precyzyjne umieszczanie na paletach z użyciem czujnika siły wykrywającego

sąsiednie opakowania - kontrola, odczyt kodów i tekstu

- dowolna czynność pakowania na stanowisku w oparciu narzędzia zainstalowane na końcu ramienia robota

- opcjonalne skanery bezpieczeństwa spowalniające lub zatrzymujące pracę paletyzera po wykryciu obecności człowieka.

Precyzja

Paletyzacja robotem zapewnia wysoką precyzję z dokładnościami do 1 mm. Linia paletyzująca lub paletyzer prowadzą pełną kontrolę procesu. Wszelkie anomalie są natychmiast wychwytywane a wadliwe produkty eliminowane do specjalnego bufora. Stosowane przez nas rozwiązania światowych liderów robotyki – firm NACHI Robotics i HANWHA Robotics pozwalają na uzyskiwanie wysokiej precyzji wynikającej z powtarzalności ruchów niezależnie z jaką prędkością pracuje ramię robota.

Dzięki zastosowaniu robotów w procesie paletyzacji zyskujemy:

- Minimalizację obszaru potrzebnego na paletyzację

- Zmniejszenie liczby pracowników do obsługi procesu

- Zmniejszamy zużycie mediów energetycznych

- Ograniczamy koszty utraty jakości PPM

- Zyskujemy precyzyjnie ułożone produkty na palecie

Wysoka niezawodność

Dzięki stosowaniu najwyższej jakości rozwiązań technologicznych oraz bogatym doświadczeniom eksploatacyjnym oferujemy wysoce niezawodne linie i roboty do paletyzacji. Nasze stanowiska i roboty posiadają oprogramowanie do monitorowania online, które zapobiega występowaniu nieplanowanych przestojów. W przypadku znacznego stopnia zużycia się dowolnej części eksploatacyjnej, system sam poinformuje o konieczności dokonania wymiany w dogodnym czasie, bez zatrzymywania linii w nieplanowanym momencie.

Pracujemy w oparciu o technologię czołowych światowych dostawców m.in. NACHI Robotics z Japonii czy HANWHA Robotics z Korei Południowej. Zapewniamy pełne wsparcie techncizne i serwis gwarancyjny raz pogwarancyjny.

Niskie koszty

Dzięki naszym sprawdzonym rozwiązaniom, zyskuje wydajne narzędzie do kompleksowej realizacji procesu paletyzacji, które wzmocni przewagę konkurencyjną twojej firmy. Praca zrobotyzowanej linii do paletyzacji pozwala osiągnąć znaczne oszczędności m.in.:

- Oszczędność mediów w pomieszczeniu gdzie odbywa się proces automatycznie be udziału człowieka

- Eliminacja do minimum kosztów robocizny związanych z paletyzacją

- Oszczędność materiałów: kleju, etykiet, przekładek dzięki 100% dokładności i powtarzalności procesu

- Oszczędność miejsca potrzebnego do realizacji procesu

- Oszczędność kosztów związanych z utratą jakości dzięki ciągłej kontroli jakość opakować i automatycznej eliminacji występujących incydentów jakościowych

Jak robotyzować paletyzację?

Paletyzacja wiąże się pracą w całym obszarze palety i linii produkcyjnej, często ze znacznym obciążeniem. Pierwotnie proces wykorzystywał paletyzowanie ręczne, lecz długie godziny spędzone na układaniu opakowań na palecie, lub ich rozładunku, jest dla Pracownika dużym obciążeniem. Wielogodzinny wysiłek fizyczny zawsze powoduje zmęczenie i uciążliwe bóle kręgosłupa. Taki charakter pracy niekorzystnie wpływa na płynność i efektywność procesu. Paletyzacja robotem może rozwiązać ten problem!

Paletyzatory i depaletyzatory to bardzo wydajne, funkcjonalne i proste w obsłudze urządzenia, które pozwalają usprawnić pracę. Automatyczny robot do paletyzacji szybko, precyzyjnie i bez zmęczenia, odbiera opakowania z określonego miejsca np. z linii produkcyjnej i układa je na palecie. Czynności wykonuje według zaprogramowanej wcześniej sekwencji, zachowując zarówno wzór, jak i określoną ilość warstw, pamiętając przy tym o używaniu przekładek międzywarstwowych. Robot paletyzujący zapewnia wydajną i precyzyjnie wykonaną pracę. Depaletyzator pełni natomiast funkcję odwrotną – nie układa opakowań na palecie, ale służy do automatycznego rozładunku.

Roboty paletyzujące, paletyzatory to maszyny proste w obsłudze, a nauka paletyzacji to bardzo szybki i łatwy proces, który polega na wskazaniu miejsca, z którego należy pobrać opakowanie, określeniu czterech naroży palety i wprowadzeniu liczby kartonów przypadających na każdy z dwóch boków podłoża. Dodatkowo można również określić ilość nakładanych warstw i wprowadzić opcję pobierania przekładek.

Paletyzacja kartonów, worków, butelek czy innych opakowań przy użyciu robota paletyzującego, przebiega o wiele szybciej i efektywniej, niż w przypadku tradycyjnych metod układania. Robot do paletyzacji gwarantuje precyzyjnie wykonaną pracę, sprawną dystrybucję i efektywną sprzedaż. Zarówno paletyzatory, jak i depaletyzatory to niezwykle istotne elementy wyposażenia każdej nowoczesnej hali produkcyjnej.

Roboty do paletyzacji

Zobacz roboty najczęściej wybierane do paletyzacji. Dostępne są roboty MZ i coboty HCR do lekkich ładunków i roboty MC i LP do ciężkich ładunków i przenoszenia całych warstw produktów.

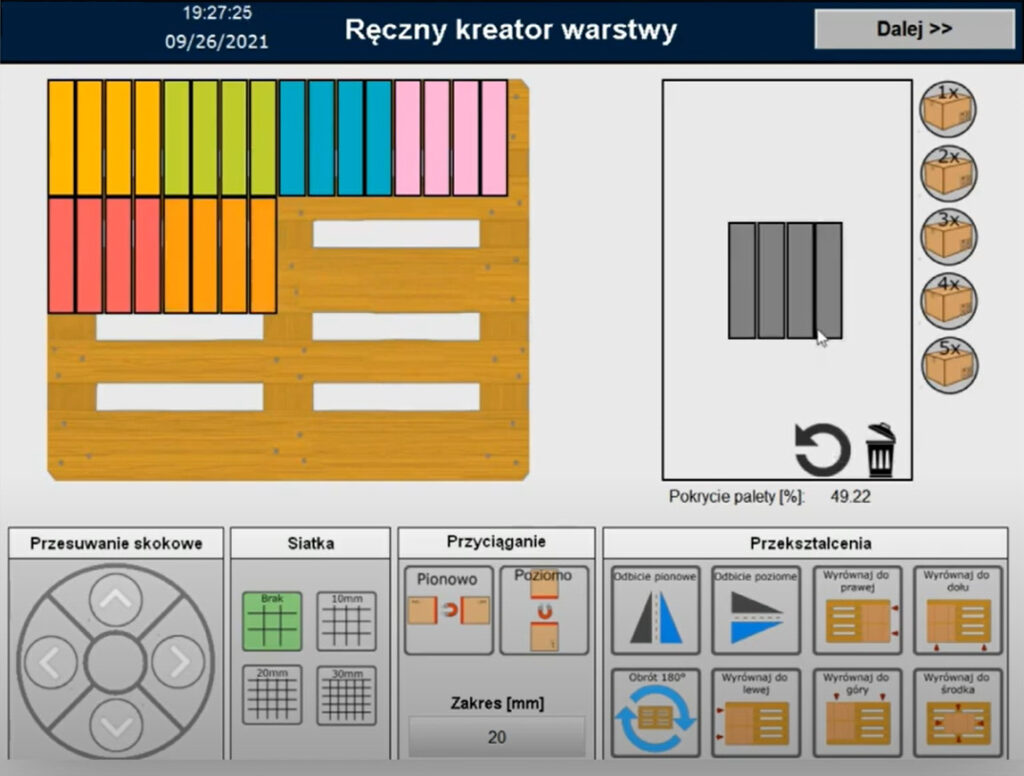

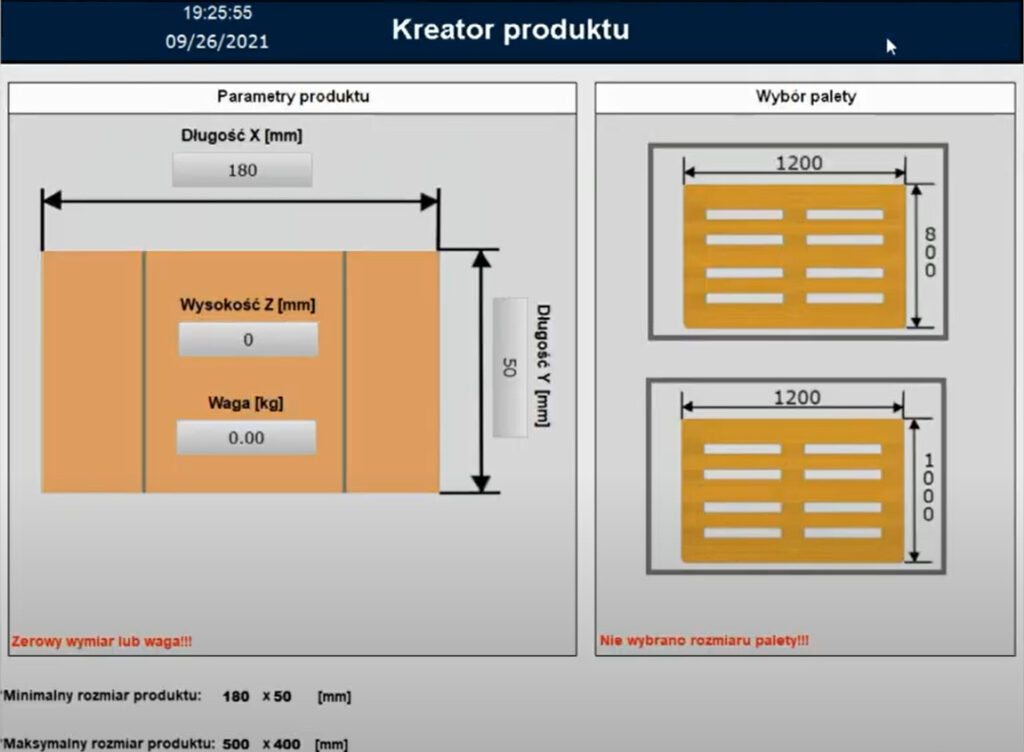

Oprogramowanie paletyzera

Paletyzery dostarczane przez CoRobotics posiadają proste i intuicyjne oprogramowanie, które umożliwia samodzielne programowanie schematów paletyzacji, wielkości palet, ilości warstw, wielkości opakowań czy obsługi przekładek. Poniżej przykłądowe ekrany interfejsu użytkownika paletyzera SmartPalletizer.

Zobacz realizacje paletyzacji

Paletyzacja worków

Paletyzacja kartonów

Paletyzacja kartonów

Paletyzacja worków

Paletyzacja odlewów metalowych

Paletyzacja puszek

Paletyzacja kartonów

Paletyzacja kartonów

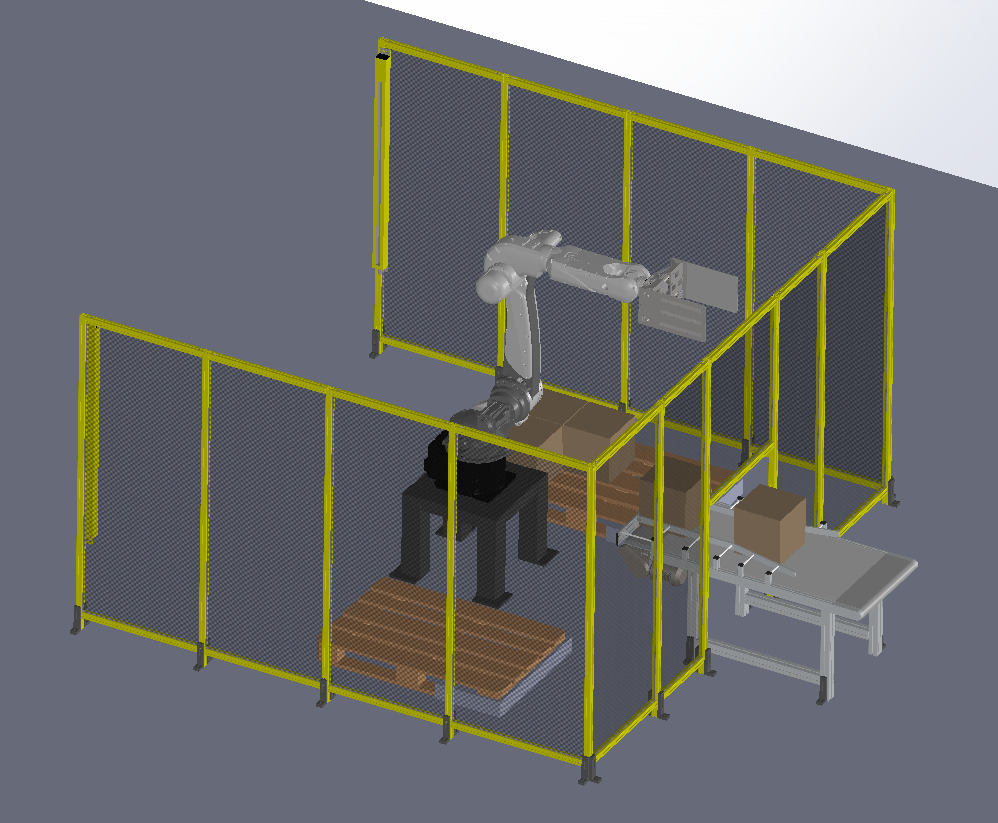

Paletyzacja kartonów cobotem

Zalety paletyzacji Cobotem

Paletyzacja Cobotem nie wymaga wiele miejsca!

Dzięki zastosowaniu przemysłowego robota współpracującego HCR nie potrzebujesz do paletyzacji dużej wolnej przestrzeni. Nasz robot do paletyzacji – cobot HCR zajmuje niewiele miejsca i można go bardzo łatwo zainstalować w każdym pomieszczeniu produkcyjnym. Paletyzatory i depaletyzatory – Cobot HCR to urządzenia kompaktowe, nie wymagają budowy specjalistycznych fundamentów i wygrodzeń, co pozwala zaoszczędzić miejsca i uniknąć dodatkowych kosztów. Jeżeli jednak potrzebujesz szybkiego robota o dużym zasięgu, który będzie w staniu obsłużyć nawet 6 miejsc paletowych, rekomendujemy roboty przemysłowe NACHI serii LP i MZ, których parametry pozwalają na paletyzację dowolnych produktów i opakowań. Roboty przemysłowe dzięki wirtualnym ścianom i klatkom mogą operować na ograniczonej przestrzeni dodatkowo wykonując inne czynności jakimi są etykietowanie, foliowanie, ważenie czy mierzenie obsługiwanych produktów. A wszystko z pełną kontrolą procesu w czasie rzyczywistym.

Roboty paletyzujące a bezpieczeństwo

Paletyzatory nie stwarzają zagrożenia i zapewniają bezpieczną pracę w pobliżu człowieka. W przypadku wykrycia ewentualnej usterki lub kolizji robot paletyzujący natychmiast wstrzyma pracę w sposób, który nie powoduje zagrożenia dla Operatora. Dla zachowania większej ostrożności można zastosować dodatkowo bariery optyczne, matę lub skaner bezpieczeństwa, które automatycznie zwolnią prędkość robota lub całkowicie zatrzyma jego pracę, jeśli w niewielkiej odległości wykryje obecność człowieka. Dzięki tym funkcjom nie musimy stosować klatek bezpieczeństwa.

Paletyzatory to elastyczna produkcja i szybkie zmiany

Intuicyjne i proste oprogramowanie paletyzerów oferowanych przez CoRobotics, pozwala na szybki programowanie dowolnych schematów paletyzacji niezależnie czy paletyzer wyposażony jest w robota przemysłowego NACHI czy cobota HCR. Dodatkowo warto wspomnieć, że przemysłowy robot współpracujący HCR jest również łatwy do programowania i posiada wbudowane schematy paletyzacji. Wyposażony jest również w intuicyjny interfejs oparty na ikonach graficznych, podobnie jak w smartfonie. Dzięki temu można go szybko i łatwo programować, zmieniać sekwencje i schematy paletyzacji, a nawet przemieszczać paletyzer pomiędzy różnymi końcówkami linii, aby płynnie reagował na potrzeby produkcji.

Wydajność paletyzacji – efektywna paletyzacja kartonów, worków, butelek i innych opakowań 24 h na dobę

Dzięki robotyzacji procesu paletyzacji kartonów, worków, butelek i innych opakowań przez zaawansowane technologicznie roboty przemysłowe, produkcja i dystrybucja towarów przebiega szybko, sprawnie i osiąga 100% wydajność. Robot do paletyzacji zapewnia precyzyjną, efektywną i wydajną pracę przez 24 h na dobę. Warto wspomnieć, że paletyzatory pozwalają odciążyć Pracowników, którzy wykonują monotonną pracę wymagającą dużego wysiłku. Dzięki zastosowaniu maszyn jak robota przemysłowego NACHI lub Cobots HCR w wielu fabrykach proces paletyzacji staje się efektywny i szybki. Przemysłowy robot współpracujący HCR lub robot NACHI to najlepsze rozwiązanie dla Twojej firmy!