Robot CNC

Automatyzacja maszyn CNC

Zobacz nasze rozwiązania do automatyzacji obsługi maszyn CNC. Stanowiska z CoRobotics do obsługi maszyn CNC pobierają produkty, ich elementy lub surowce z transporterów, podajników, matryc, kartonów i innych formatów logistycznych. Następnie umieszczają jest w pożądanym miejscu maszyny, dokonując szeregu czynności pośrednich jak kontrola, odmuchiwanie, olejowanie, pomiar, reorientacja i walidacja. Nie ma tu znaczenia czy mówimy o prasie krawędziowej, wykrawarce, prasie rewolwerowej, hydraulicznej czy centrum tokarskim lub frezerskim.

Roboty połączone z maszyną CNC, kontrolują na bieżąco realizowane operacje i natychmiast reagują na wszelkie sygnały z maszyny np. uszkodzenie frezów informując operatora.

Jak zrobotyzować obsługę maszyny CNC?

Faktem jest, że maszyny CNC, centra obróbcze potrzebują szybkiego, wydajnego i ściśle określonego układu hali produkcyjnej. Jednocześnie wymagają obsługi przez Pracowników do załadunku, rozładunku i obsługi operacji wykończeniowych.

Operatorzy mogą obsługiwać wiele maszyn. Jednak dla wielu wysoko wykwalifikowanych Pracowników rutynowe obsługa może stać się nudna. W efekcie prowadzi to do błędów, przestojów, utraty wydajności, a nawet wypadków.

Automatyzacja maszyn CNC pozwala na automatyzację powtarzalnych zadań. Wykwalifikowani ludzie nadal są potrzebni, by nadzorować pracę robotów i reagować na zaplanowane zmiany. Robotyzacja pozwala na tej samej powierzchni produkcyjnej pracować 24h zwiększając produktywność Zakładu i wykorzystanie powierzchni. Roboty CNC to doskonały sposób na zwiększenie wydajności produkcji.

Dlaczego robotyzować obsługę maszyn?

- Wysokie ryzyko wypadków przy pracy – obsługa prasy, praca w środowisku agresywnym chemicznie

- Monotonne czynności – powtarzalna w dłuższym czasie czynności powodująca błędy wynikające z rutyny

- Wymagające dużej siły fizycznej – rozładunek, załadunek ciężkich detali

- Wymagana duża precyzja – zaawansowana obróbka materiałowa

- Potrzeba wykorzystania maszyn i budynków przez 24 godziny mająca na celu zwiększenie konkurencyjności firmy

Dlaczego warto zdecydować się na automatyzację maszyn CNC?

- Wzrost efektywności produkcji

- Wysoka wydajność

- 100% powtarzalna jakość

- Bezpieczeństwo dla personelu

- Niskie koszty operacyjne

- Przekazywanie danych w czasie rzeczywistym

- Krótkie czasy cyklu

- Możliwość pracy maszyn przez 24h

- Obsługa kilku maszyn o dłuższych czasach cyklu jednym robotem

Robot CNC - przykładowa funkcjonalność

- sterowanie maszynami CNC i tradycyjnymi poprzez sygnały analogowe lub cyfrowe [sterowanie FANUC/SIEMENS/Inne]

- współpraca z podajnikami buforującymi na kilka godzin surowiec dla maszyny i wyroby gotowe

- informacja online w czasie rzeczywistym o produkcji

- współpraca z maszyną pod kątem zużycia frezów i innych narzędzi mających wpływ na jakość procesu

- integracja z zewnętrznymi systemami bezpieczeństwa

- obsługa bramek zatrzymania, czytników

- odmuchiwania i zanurzanie w oleju

- kontrola wymiarów detali czujnikami wizyjnymi lub dedykowaną maszyną

- kontrola umieszczenia elementu w gnieździe z użyciem czujnika siły

- podwójny chwytak pozwalający na jednoczesny załadunek i rozładunek maszyny

- dowolna czynność przy maszynie w oparciu narzędzia zainstalowane na końcu ramienia robota CNC

Robot lub cobot do załadunku i rozładunku maszyny

Zastosowanie robota pozwala na samodzielne, szybkie i łatwe zrobotyzowanie obsługi maszyny CNC. W tym celu możemy wybrać gotowy zestaw składający się z:

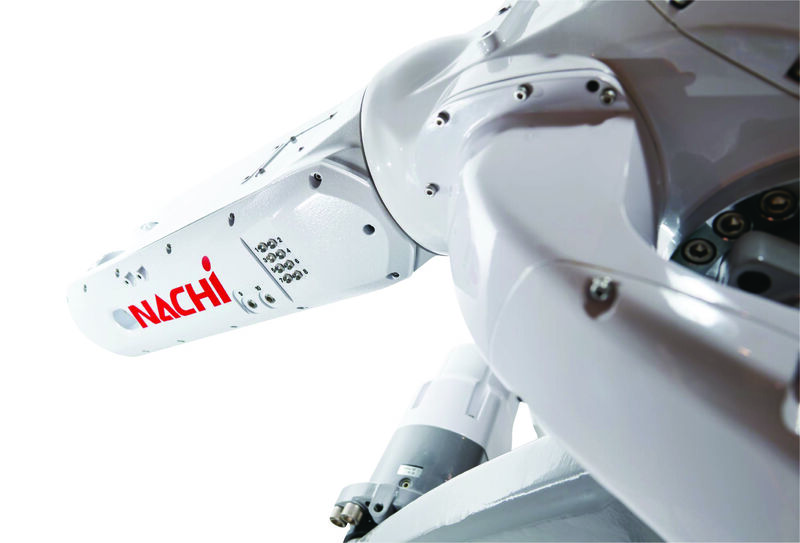

- Robota NACHI lub HCR

- Gotowych celek zrobotyzowanych z EasyRobotics

- Chwytaka pojedynczego lub podwójnego

- Opcjonalnie skaner bezpieczeństwa [w przypadku ostrych i niebezpiecznych elementów do obróbki]

Zestaw taki pozwala na szybkie ustawienie obok maszyny i podłączenie sygnałów z maszyny do sterownika robota. Typowo podłączamy sygnały start, stop, awaryjne wyłączenie. Dodatkowo możemy wprowadzić sygnały informujące o zużyciu narzędzi w maszynie. Podłączenie jest stosunkowo proste w oparciu o dedykowane i oznaczone do tego celu wejścia i wyjścia cyfrowe. Następnie ustawiamy parametry detalu i formatkę na której będą przygotowane detale do obróbki. Programowanie to tylko kilka minut i jest niezwykle prosta i intuicyjna dzięki dedykowanemu oprogramowaniu.

Roboty do obsługi maszyn CNC

Zobacz roboty najczęściej wybierane do obsługi maszyn. Dostępne są roboty MZ/MC/MR/SRA i coboty HCR do operacji załadunku i rozładunku maszyn CNC, pras krawędziowych, pras hydraulicznych i mimośrodowych, wykrawarek czy innych dedykowanych maszyn. Szerokie spektrum robotów w naszej ofercie pozwoli Tobie zrobotyzować obsługę każdego rodzaju maszyny, niezależnie czy mówimy tu o lekkich robotach MZ, cobotach HCR czy 7-mio osiowych robotach MR, które dzięki swojej konstrukcji dostaną się do najbardziej niedostępnych przestrzeni w maszynie.

Prosta i szybka integracja ze sterowaniem maszyny CNC

Przy robotyzacji obsługi maszyn kluczowym zagadnieniem jest szybkie połączenie robota z maszyną. W naszej codziennej praktyce wypracowaliśmy sobie metody szybkiego podłączenia do sterowania maszyn CNC niezależnie czy mówimy tu o sterowaniu analogowym czy cyfrowym firmy SIEMENS, FANUC lub innych. Posiadamy gotowe interfejsy programowe, które są wbudowane w aplikacje i umożliwiają nawiązanie komunikacji z maszynami CNC wykorzystującymi Ethernet lub High Speed Serial Bus (HSSB).

Automatyzacja maszyn CNC - przykłady

Załadunek maszyny CNC

Załadunek 2 maszyn robotem NACHI

Obsługa maszyny CNC

Załadunek szlifierki

Załadunek maszyny Hyundai WIA

Obsługa 2 maszyn CNC

Załadunek maszyny CNC

Załadunek 2 maszyn robotem NACHI

Obsługa maszyny do odlewów z aluminium

Gotowe celki zrobotyzowane do załadunku i rozładunku maszyn

EasyPedestal

EasyPedestal to opłacalna i inteligentna podstawa robota, która może być obsługiwana nie tylko w połączeniu z wysoce wydajnymi celami robotów EasyRobotics, ale także używana indywidualnie. Nadaje się do różnych typów maszyn, na różnych stanowiskach pracy.

Podstawa robota ER jest bardzo elastycznym produktem, a gdy działa w połączeniu z innymi celami robotów, takimi jak ProFeeder Compact, daje niesamowite rezultaty. Jest to jedyne w swoim rodzaju narzędzie, które zostało stworzone w celu wspierania użytkowników w podnoszeniu wydajności robota współpracującego.

Profeeder Light

Ta cela robotyczna składa się z modułu podstawowego z 1 elastyczną, ręcznie wyjmowaną tacą na części, przeznaczoną do obsługi wszelkiego rodzaju części. Może być stosowany w niezliczonych branżach, zwiększając wartość automatyzacji aplikacji.

Moduł podstawowy, ProFeeder Light, można rozszerzyć do ProFeeder, gdy potrzebna jest zwiększona wydajność, lub używać razem z innymi wzajemnie kompatybilnymi produktami EasyRobotics.

Możliwość rozbudowy

Robotcell jest wzajemnie kompatybilny z innymi produktami EasyRobotics i może być używany jako pierwsza faza w pełni zautomatyzowanej produkcji.

Profeeder Table

Jak wszystkie produkty firmy EasyRobotics, ta cela robocza robota jest wykonana z wysokiej jakości materiałów, które zapewniają wysoką trwałość i niezawodność.

Stół ProFeeder jest wykonany ze stali malowanej proszkowo, co nadaje systemowi elegancki wygląd i sprawia, że jest on trwały. Rozmiar systemu jest idealny do ustawienia na podłodze linii montażowej bez obaw o jego przechowywanie.

Idealnie nadaje się do następujących zastosowań:

Cięcie

Wykańczanie i polerowanie

Gratowanie

Szlifowanie

Spawanie

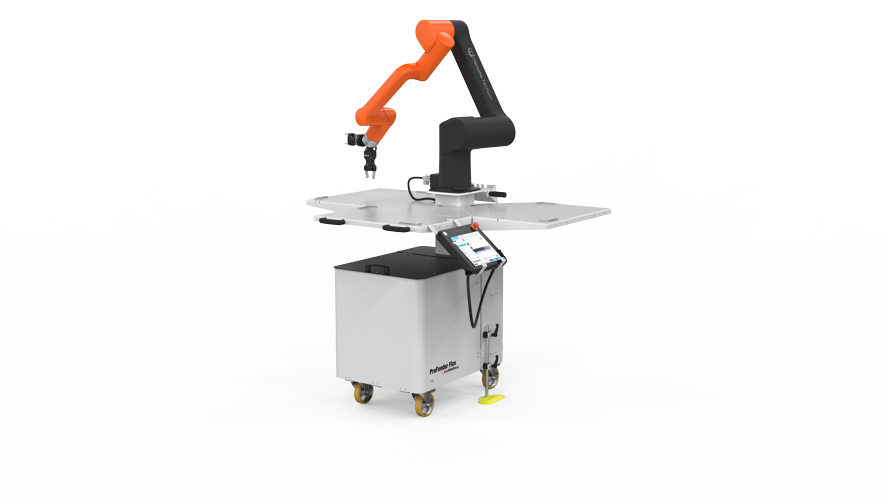

Profeeder Flex

ProFeeder Flex to cela robota, która umożliwia elastyczne manewrowanie na terenie fabryki. Jest to bardzo kompaktowy i elastyczny ProFeeder.

EasyRobotics jest pionierem w projektowaniu innowacyjnych produktów, które pomagają producentom w uzyskaniu maksymalnej wydajności w krótszym czasie, a nowy ProFeeder Flex jest jednym z nich, stworzonym w celu zapewnienia elastyczności i łatwości przenoszenia w zakładzie produkcyjnym do/z linii montażowych lub maszyn. Producenci mogą wybrać ProFeeder Flex zgodnie ze swoimi wymaganiami spośród trzech wyróżniających się modeli:

FlexBase – wyposażony w komorę na kontroler i cokół

FlexOne – jeden stół

FlexThree – trzy stoły

Profeeder X

ProFeeder X jest przeznaczony do obsługi większych serii produkcyjnych. Stanowisko może być wyposażone w wiele opcji tac w zależności od wymagań. Rozwiązanie to pozwala na skróceniu czasu cyklu i przyspieszenie produkcji przy większych wolumenach produkcji. ProFeeder X może obsługiwać do 10 tac, które są dobrze przystosowane do produkcji małych i dużych serii.

System jest w pełni zautomatyzowany i bardzo kompaktowy, co umożliwia na współpracę z dowolną maszyną. Dzięki 2, 5 lub 10 tackom, ProFeeder X może być używany do dowolnego zadania w ograniczonym czasie. Podobnie jak ProFeeder Compact, ta aplikacja jest również dostępna w dwóch wariantach opartych na systemie blokowania. System Airlock może blokować tace poprzez sprężanie powietrza, a Mechlock wykorzystuje blokadę mechaniczną. System blokowania jest przydatny w ochronie operatora, aby zapobiec ingerencji w procesy, a także pomaga w utrzymaniu wydajności.

Profeeder X-XL

Wdrożenie modelu X-XL może znacząco zwiększyć wydajność produkcji. Dzięki dużej wydajności produkcyjnej i powiększonemu schowkowi ta zrobotyzowana platform a jest nowym „must-have” dla każdego zautomatyzowanego zakładu produkcyjnego.

Sprawdźmy specyfikacje platformy:

Jej wymiary to 1050 x 1420 x 920 mm;

Może pomieścić do 5 tac 780x620mm;

Maksymalna wysokość części może wynosić do 160mm;

Maksymalne ugięcie nie przekracza 2,5 mm pod obciążeniem 90 kg na tacę.

Podobnie jak inne modele Compact i X, ta platforma robota współpracuje z dwoma systemami blokowania tac – Mechlock (blokada mechaniczna) i Airlock (blokada sprężonego powietrza. *Wymaga podłączenia sprężarki). System blokowania jest przydatny do zwiększenia bezpieczeństwa w miejscu pracy i ochrony operatora przed obrażeniami.

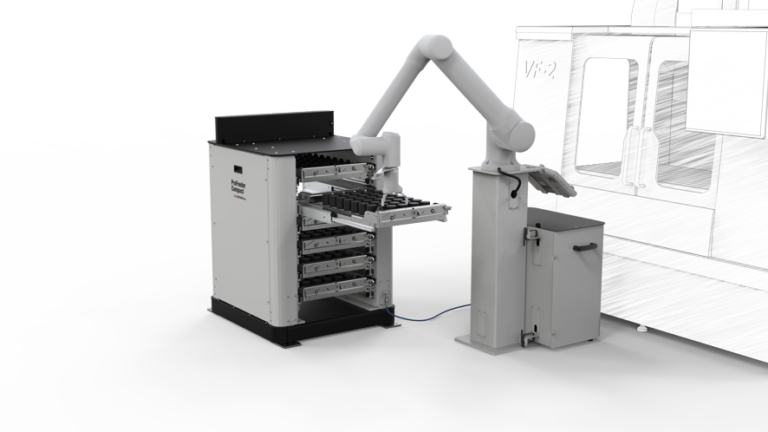

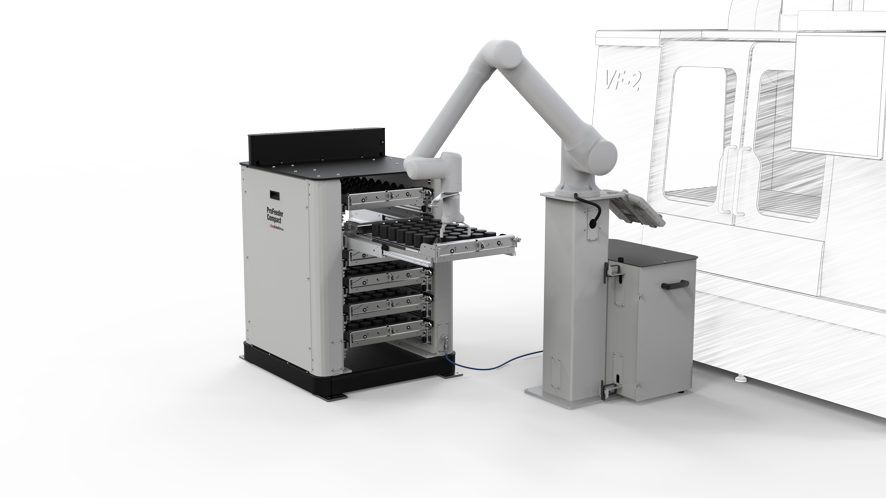

Profeeder Compact

ProFeeder Compact to jedyna w swoim rodzaju cela o kompaktowych wymiarach, którą można łatwo przemieszczać po zakładzie produkcyjnym. ProFeeder Compact zajmuje mniej miejsca w fabryce i wspiera masową produkcję. ProFeeder Compact jest obsługiwany, gdy znajduje się przed maszyną. Ten produkt firmy EasyRobotics to potężna zrobotyzowana cela, która ma kompaktowe wymiary, które wspierają produkcję.

Pod względem elastyczności ProFeeder Compact jest bardzo wszechstronny, ponieważ może działać pod czterema różnymi kątami, co sprawia, że ruch jest nieograniczony. ProFeeder X w połączeniu z EasyPedestal może służyć jako podpora do przechowywania. System jest wysoce mobilny, dlatego można go umieścić w pobliżu różnych typów maszyn w celu dalszego zwiększenia wydajności.

ProFeeder Compact ma prostą konstrukcję zawierającą do 10 tac, które można wykorzystać do łatwej obsługi produkcji bez konieczności dodatkowego przezbrojenia.

Profeeder Compact XL

Rozwiązania automatyzacji w produkcji mają na celu uproszczenie i przyspieszenie przepływów pracy, uchronienie pracowników przed nieefektywną monotonną pracą ręczną oraz przekwalifikowanie ich do bardziej wykwalifikowanej i interesującej pracy, poprawiając dokładność i wydajność procesu produkcyjnego. Złożoność produkcji jest znacznie zmniejszona dzięki wydajnym rozwiązaniom automatyzacji, które można wykorzystać do ulepszenia większości znanych zastosowań przemysłowych.

Wydajne rozwiązanie automatyzacji jest wielofunkcyjne. Profeeder Compact X może być używany w wielu branżach, może wydajnie współpracować z przenośnikiem, współpracować z jedną lub kilkoma maszynami CNC jednocześnie. Można go łatwo przemieszczać po obszarze produkcyjnym i wykorzystywać jako główny lub dodatkowy magazyn na różnego rodzaju części o wysokości do 160 mm. Może usprawnić operacje produkcyjne, optymalizując przepływy pracy i zastępując podatną na błędy pracę ręczną dokładnymi zautomatyzowanymi procedurami.

Profeeder Compact robot

Produkt może być wyposażony w 3 tace 60kg dla maksymalnej wysokości detali 120mm lub 4 tace 120kg dla max. 80mm.

Ta kompaktowa cela robota jest jak dodatkowa para rąk do produkcji mniejszych serii. Model jest przystępny cenowo i pozwala na wykorzystanie go jako pierwszy kroku w kierunku pełnej automatyzacji produkcji.

Główną cechą tego produktu jest jego niezwykle kompaktowa konstrukcja. To tylko H: 1165 mm, W: 770 mm, L: 920 mm. Dzięki temu robot Compact bez problemu może być używany w każdym warsztacie – nawet najmniejszym.

Profeeder R

Cela ta jest niezwykle pojemna i łatwa w obsłudze. Umożliwia ciągłą pracę maszyny CNC do 24 godzin.

Obsługa szafy przez operatora – umieszczanie nowych części zamiast obrabianych oraz odbiór obrabianych części może odbywać się jednocześnie z pracą Twojej maszyny CNC.

Jest całkowicie bezpieczny w użyciu – dzięki systemowi Airlock, który pozwala niezawodnie zablokować dowolną z 10 tac za pomocą przycisku, a także szybko ją odblokować. (*wymaga podłączenia sprężarki powietrza).