Cobot | Roboty przemysłowe | Podajniki wibracyjne | Automatyzacja i Robotyzacja

Dystrybucja w Polsce rozwiązań największych globalnych dostawców

Roboty przemysłowe NACHI

Roboty przemysłowe NACHI doskonale sprawdzają się w miejscach gdzie ważna jest szybkość, precyzja i niezawodność. NACHI jest jednym z najstarszych producentów robotów na świecie z doświadczeniem od 1968 roku. Obecnie gama modelowa robotów obejmuje kilka rodzin i ponad 60 modeli, które dedykowane są do niemal wszystkich zastosowań w przemyśle. Począwszy od robotów 4/6 i 7-osiowych aż po roboty SCARA. Niezależnie czy potrzebujesz robota do manipulowania drobnymi częściami z powtarzalnością 0,014 mm czy do przenoszenia całych nadwozi w branży samochodowej o masie 1700 kg to znajdziesz w ofercie NACHI odpowiednie rozwiązanie. Potrzebujesz ultra szybkie roboty 4-osiowe do paletyzacji, roboty do lakierowania w strefach wybuchowych Ex, ramie robota o geometrii dedykowanej do spawania czy model 7-mio osiowy, którego geometria pozwala dotrzeć do najbardziej skomplikowanych zakamarków maszyn CNC. A do tego lekkie roboty przemysłowe MZ z legendarnym modelem MZ-07, który jest najszybszym robotem 6-cio osiowym w swojej klasie.

Roboty NACHI to nieograniczone możliwości robotyzacji linii produkcyjnych i maszyn. Twoja produkcja osiągnie niespotykaną dotąd wydajność. Dzięki technologii NACHI wzmocnisz swoją konkurencyjność na globalnym rynku.

„Kompaktowy, lekki, 6-cio osiowy robot przemysłowy NACHI MZ07F jest obecnie najszybszym na świecie robotem w swojej klasie.

Roboty serii MZ

to szybkość, precyzja

i niezawodność

Coboty - roboty współpracujące HCR

Roboty współpracujące HANWHA HCR pozwalają zrobotyzować każdy rodzaj produkcji, niezależnie czy mówimy tu o nisko, średnio czy wysokoseryjnej. Do tego intuicyjnie proste programowanie, bezpieczna praca z ludźmi, liczne akcesoria i narzędzia montowane w systemie Plug'n'Play, pozwalają na szybkie samodzielne wdrożenie w twojej firmie.

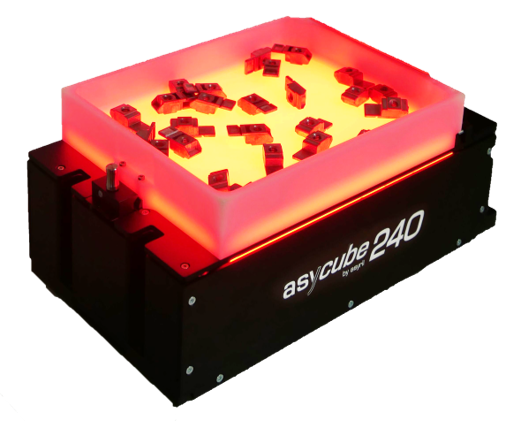

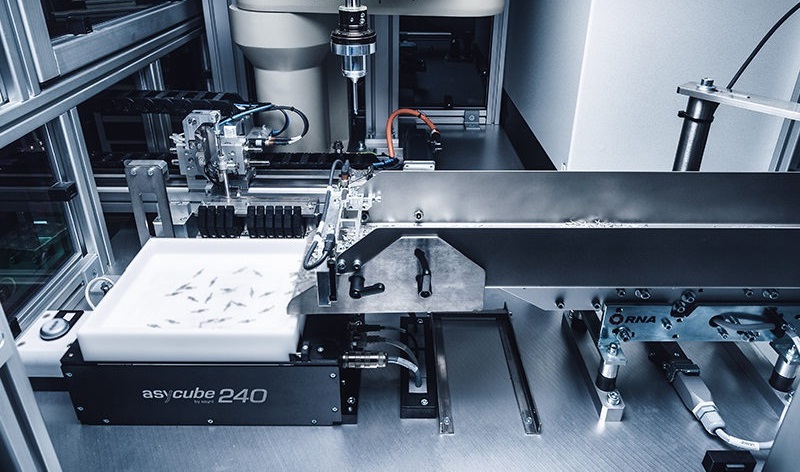

Elastyczne systemy podawania - podajniki wibracyjne Asyril

AsyCube to innowacyjne systemy pozycjonowania i sortowania elementów szwajcarskiej firmy ASYRIL, to stół wibracyjny wykorzystujący opatentowaną technologię wibracji 3D, wzbogaconą dodatkowo o system wizyjny EYE+ oraz podświetlenie BackLight, które wraz ze specjalnie wyprofilowanymi płytami są w stanie precyzyjnie, szybko i delikatnie rozdzielić, posortować oraz pozycjonować niemal 99% występujących elementów o dowolnych kształtach i geometrii. Podajnik wibracyjny AsyCube współpracuje z większością dostępnych na rynku robotów i cobotów.

Elastyczne systemy podawania elementów do robotów Asyril AsyCube, dają niespotykaną dotąd możliwość orientowania dowolnych elementów, czyniąc twoje linie produkcyjne i maszyny dostosowanymi do szybkich zmian. Od teraz możesz szybko reagować na potrzeby Klientów, bez konieczności przebudowy systemów produkcyjnych.

Automatyzacja i Robotyzacja

CoRobotics wspólnie z autoryzowanymi Integratorami oferuje kompleksowe rozwiązania z zakresu automatyzacji i robotyzacji produkcji. Nasze kluczowe kompetencje to analiza potrzeb, przygotowanie koncepcji z niezbędnymi wyliczeniami i symulacjami procesu. Niezależnie czy chodzi o stanowisko zrobotyzowane, linię produkcyjną, paletyzer, celę spawalniczą czy maszynę dedykowaną do danego procesu. Nasze unikatowe doświadczone zdobyte w wielu wdrożeniach w połączeniu z dystrybuowanym sprzętem wiodących światowych marek oraz siecią sprawdzonych integratorów, pozwalają na sprostanie najtrudniejszym wyzwaniom.

W zakresie naszych rozwiązań są koncepcje robotyzacji, doradztwo, projekt, dostawa urządzeń, integracja, uruchomienie, szkolenie w zakresie robotów przemysłowych, cobotów, stołów wibracyjnych i robotów mobilnych. Naszymi Klientami są zarówno małe i średnie przedsiębiorstwa jak również duże międzynarodowe koncerny. Najczęściej robotyzujemy procesy pakowania, paletyzacji, pick and place, spawania, montażu, szlifowania, malowania, obsługi maszyn, przenoszenia ładunków. Do naszych koncepcji dołączamy analizy opłacalności, by decyzję podejmować w oparciu o twarde fakty.

Na pierwszym miejscu stawiamy na zrozumienie potrzeb Klienta, dobór optymalnego i dobrze dopasowanego rozwiązania. Do projektów podchodzimy z profesjonalizmem, otwartością i kreatywnością.

Nasi Inżynierowie przygotują optymalną strategię robotyzacji twoich procesów produkcyjnych. Zaprezentujemy koncepcję z rysunkami 2D/3D, wyliczeniami wydajności i czasu zwrotu z inwestycji, tak by wdrożenie było szybkie, a eksploatacja dostarczała wymaganych rezultatów operacyjnych i biznesowych.

Chwytaki, czujniki, systemy wizyjne

Oferujemy szerokie spektrum narzędzi dla robotów w postaci chwytaków, czujników siły, systemów wizyjnych, dodatkowych osi jednych dla robota, obrotników, stołów, podstaw, podajników, automatycznych magazynków detali. W naszej ofercie znajdziesz narzędzia pozwalające zrobotyzować niemal każdą aplikację czy proces produkcyjny, niezależnie czy mówimy o paletyzacji, spawaniu, szlifowaniu, malowaniu, klejeniu, obsłudze maszyn czy innych procesach. Zachęcam do kontaktu. Przygotujemy dla Ciebie kompletne rozwiązanie spełniające twoje oczekiwania.

Łatwe w konfiguracji i instalacji chwytaki i rozwiązania Plug'n'Play firmy OnRobot, pozwolą szybko i samodzielnie zrobotyzować dowolny proces. Niezależnie czy mówimy tu o paletyzacji, obsłudze maszyn czy dowolnym innym procesie.

Jak zacząć robotyzację?

Szkolenia

Realizacje

Serwis

Jesteśmy do twojej dyspozycji.

Cobot - czytaj więcej

Co to jest Cobot?

Cobot – czym jest? Roboty współpracujące – coboty, to sprawdzone od kilku lat rozwiązanie do robotyzacji niemal dowolnych procesów, które są łatwo programowalne, a do tego mogą bezpiecznie pracować z Człowiekiem. Łatwość programowania pozwala wdrażać je w miejscach gdzie wymagane

Cobot spawalniczy – czym jest?

Cobot spawalniczy – czym jest? Spawanie historycznie zawsze było procesem trudnym, który wymaga skupienia i precyzji. Z drugiej strony spawanie to ciężka praca w trudnych warunkach, co nie sprzyja wysokiej wydajności i powtarzalności spoin. CoRobotics ze swoimi autoryzowanymi integratorami stworzył

ROBOTY WSPÓŁPRACUJĄCE HANWHA

ROBOTY WSPÓŁPRACUJĄCE HCR Roboty współpracujące – ang. collaborative robots tzw. cobot’y. Roboty te mają ograniczona prędkość i siłę dzięki czemu mogą pracować obok Człowieka. Dodatkowo posiadają wbudowane systemy bezpieczeństwa, które w przypadku kolizji minimalizują jej skutki. Elastyczny | Bezpieczny |

Właściwości robotów przemysłowych a cobotów

Roboty przemysłowe a coboty W codziennej pracy często spotykam się z pytaniami czym różnią się coboty [roboty współpracujące] od robotów przemysłowych? Pytanie jest jak najbardziej uzasadnione. W jednym i drugim przypadku mamy do czynienia z podobnym ramieniem robotycznym. Okazuje się

Jak skutecznie wdrożyć Cobota?

Automatyzacja, Robotyzacja? Dziś już nikt nie pyta czy ale jak robotyzować? Żeby robotyzacja była efektywna niezbędna jest wiedza o procesie produkcyjnym, ale również o robotach. Przygotowałem dla Ciebie dedykowaną stronę internetową „Automatyzacja i Robotyzacja Przemysłu – Jak zacząć?” Znajdziesz tam:

Robotyzacja i Automatyzacja Produkcji Przemysłowej - Aktualności

Wyróżnienie na targach STOM 2024 w Kielcach

Cieszę się ogromnie z ogłoszenia, że spawarka laserowa hasztagLaserWeld, produkowana przez JM-TRONIK i dystrybuowana przez CoRobotics, została wyróżniona na tegorocznych targach STOM 2024.To ogromny zaszczyt być

TRENDY W ROBOTYZACJI

Nowsze postęp w dziedzinie robotyki stale rozwija się, oferując fascynujące trendy i innowacje, które zmieniają sposób, w jaki ludzie pracują, uczą się i żyją. Raport

Spawanie cobotem dużych elementów

Ostatnio mieliśmy niezwykłą okazję wdrożyć innowacyjne rozwiązanie w fabryce naszego Klienta – spawanie za pomocą dwóch cobotów jednocześnie, zamocowanych do sufitu, które współpracują z dużym

Roboty SCARA EC już w Polsce!

Z przyjemnością ogłaszamy wprowadzenie do naszego portfolio innowacyjnych robotów SCARA japońskiej firmy NACHI! NACHI SCARA EC06 i EC10 to nowoczesne rozwiązania, które zmieniają sposób, w

CoRobotics członkiem Forum Automatyki i Robotyki Polskiej (FAiRP)

CoRobotics dołączyła do Forum Automatyki i Robotyki Polskiej (FAIRP) – organizacja ta zrzesza firmy działające w obszarze automatyzacji i robotyzacji polskiego przemysłu. FAIRP to organizacja i

Zobacz nasze e-booki - automatyzacja przemysłu

Roboty współpracujące

FAKTY i MITY

Poczytaj broszurę , która pokazuje rolę i miejsce robotów współpracujących w nowoczesnych fabrykach

Roboty współpracujące

GDZIE I JAK WDRAŻAĆ?

Poznaj miejsca gdzie roboty współpracujące najlepiej się sprawdzają i gdzie wzmacniają efektywność produkcji.

Spawanie Cobotem

PRAKTYCZNY PORADNIK

Dowiedz się jak efektywnie wdrożyć spawanie Cobotem w twojej firmie, nawet w krótkich i średnich seriach produkcyjnych.

Roboty czy Coboty

CO WYBRAĆ?

Poznaj różnice pomiędzy robotami przemysłowymi a cobotami. Kiedy stosować roboty a kiedy coboty – poznaj odpowiedzi.

Roboty przemysłowe i coboty - jakie dają korzyści?

- Niskie koszty produkcji

- Kontrola kosztów produkcji niezależnie od zmian na rynku pracy

- Stabilna wydajność przez 24h

- Powtarzalność procesów

- Wysoka jakość i precyzja

- Optymalizacja zużycia materiałów w wyniku minimalizacji błędów

- Bezpieczna praca w trudnych warunkach środowiskowych

- Ochrona zdrowia Pracowników

- Integracja maszyn i urządzeń w systemy produkcyjne eliminująca „wąskie gardła”

- Kontrola operacji i wydajności

- Szybka stopa zwrotu z inwestycji w automatyzację